5 Different Types of Audits to Evaluate Your Supplier

Factory audit remain an undervalued tool among importers to evaluate suppliers and minimize their risk. Here are five different types of audits to help you evaluate your suppliers and minimize risk in your supply chain.

There are many risks associated with importing from Asia. Unqualified suppliers can subject your supply chain to a variety of disruptions, from factory disasters and negative publicity to legal repercussions and quality issues.

There are many risks associated with importing from Asia. Unqualified suppliers can subject your supply chain to a variety of disruptions, from factory disasters and negative publicity to legal repercussions and quality issues.

There are many risks associated with importing from Asia. Unqualified suppliers can subject your supply chain to a variety of disruptions, from factory disasters and negative publicity to legal repercussions and quality issues.

Many importers understand the value of quality control inspections to verify product quality before shipment. But factory audits remain an undervalued tool among importers to evaluate suppliers and minimize their risk.

While audits often come at an upfront cost, the long-term value they provide can be tremendous. Factory audits can help you verify the legitimacy, trustworthiness and reliability of your suppliers to limit risk in your supply chain.

Different types of audits can serve different purposes. They can help you:

- Ensure compliance with retailer requirements

- Ensure compliance with international labor and environmental laws

- Evaluate your supplier’s quality management system and production capabilities

Here are five different types of audits to help you evaluate your suppliers and minimize risk in your supply chain.

1. Social compliance audit

Social compliance audits are sometimes also called social audits, ethical audits or social accountability audits. Importers rely on this type of factory audit to verify and monitor their supplier’s working conditions for compliance with international labor standards.

Social compliance audits also help retailers and brands manage social compliance risks that could impact their company’s reputation. Unethical labor practices and factory disasters like fires, collapses and explosions can all result in negative publicity for brands (related: Social Compliance for Garment Factories: How You Can Avoid Disasters).

After an influx of social compliance issues in the early 21st century, various international non-profits, government organizations and specific global retailers each created different factory audit standards for evaluating social compliance.

Many major retailers historically had their own social compliance audit frameworks. But retailer-specific frameworks are becoming less common as the retail industry attempts to move towards a single, harmonized standard.

The lack of a standardized audit framework has led to “audit fatigue”  in the industry, as suppliers have been subject to many different social compliance audits for different retailers. Many retailers now accept international frameworks, rather than requiring their own specialized audit, including:

in the industry, as suppliers have been subject to many different social compliance audits for different retailers. Many retailers now accept international frameworks, rather than requiring their own specialized audit, including:

- Walmart: Accepts eight different factory audit standards, including SA8000 and SMETA

- Disney: Accepts eight different factory audit standards, including SA8000 and SMETA

- Target: Accepts the International Labour Organization’s Better Work program’s audits but still maintains their own framework as well

SA8000 audit

SA8000 is a voluntary standard based on the UN Declaration of Human Rights and International Labour Organization (ILO) conventions. The standard was created in 1997 by Social Accountability International, a leading global non-profit organization in the human rights field.

SA8000 audits are a good choice for importers who don’t need to meet a specific retailer requirement or are conducting a social compliance audit for the first time. Compliance with this factory audit standard sets a strong foundation for compliance with local laws and international human rights norms.

SA8000 audits assess nine major areas of the supplier’s working conditions, including:

- Child labor

- Forced labor

- Health and safety

- Freedom of association and collective bargaining

- Discrimination

- Disciplinary practices

- Working hours

- Renumeration

- Management system

The auditor typically assesses the factory’s conditions by interviewing workers and management staff, reviewing documents and conducting a walkthrough of the facility.

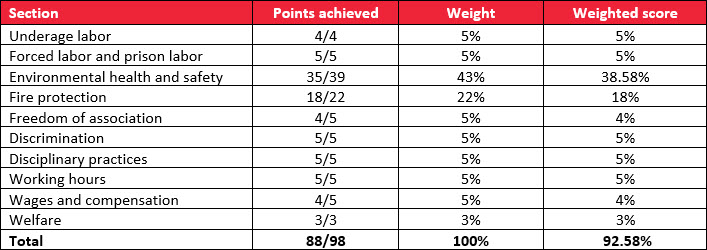

A SA8000 audit typically includes a clear point system for evaluating the supplier based on their compliance with each point. This makes it easy to identify nonconformities and needed corrective actions in specific areas.

SMETA audit

Supplier Ethical Data Exchange (Sedex) is a non-profit membership organization dedicated to improving ethical business practices in global supply chains.

Sedex’s factory audit standard is known as the Sedex Members Ethical Trade Audit (SMETA). SMETA audits are one of the most common factory audit standards in the world—Sedex currently boasts over 50,000 members.

SEDEX also has its own online platform, in which importers can access official audit reports and view progress on corrective actions. And auditors can upload any kind of social audit on the platform, including SA8000 audits.

SMETA has two audit frameworks: a 2-pillar audit and a 4-pillar audit. All SMETA audits include the following elements:

- Universal rights covering the United Nations Guiding Principles (UNGP)

- Management systems

- Entitlement to work

- Subcontracting and homeworking

- Environment (shortened)

In addition to the above frameworks, the 2-pillar audit includes verifying:

- Labor standards

- Health and safety

The 4-pillar audit includes all the above checks in addition to the following two modules:

- Environment (extended) – this pillar replaces the shortened version above

- Business ethics

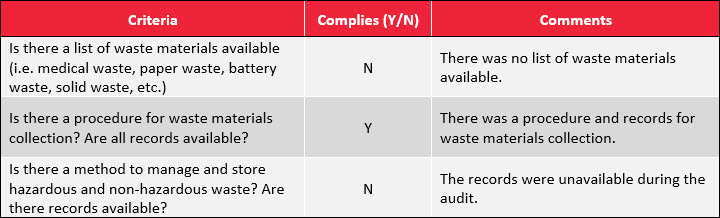

One of the benefits of a 4-pillar SMETA audit is that it also includes a section for environmental compliance. This offers you a basic assessment of social and environmental compliance without the need for a separate environmental audit.

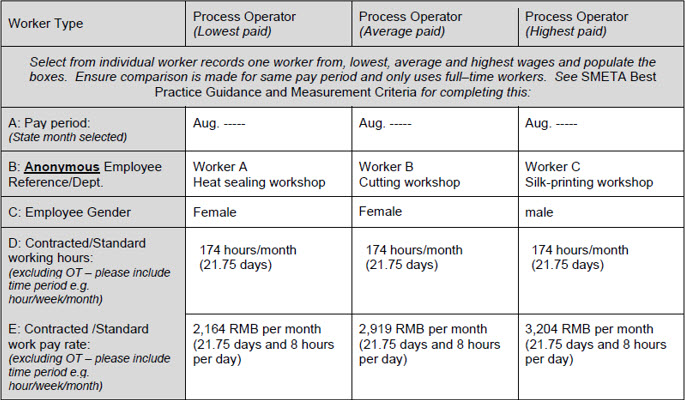

SMETA audits are more detailed in some respects than SA8000 audits. The SMETA audit, for instance, includes more detailed information about worker wages across pay ranges:

Importers with no experience with social compliance might find the SMETA report harder to interpret. You might consider starting off with a simpler framework like SA8000. Then, if needed, you could consider a SMETA audit once you have a stronger grasp on your supplier’s compliance.

Importers with no experience with social compliance might find the SMETA report harder to interpret. You might consider starting off with a simpler framework like SA8000. Then, if needed, you could consider a SMETA audit once you have a stronger grasp on your supplier’s compliance.

2. Quality system audit

A second common type of factory audit is a quality system audit, or simply, a quality audit. Importers typically rely on quality audits to understand a supplier’s production capabilities and internal quality controls.

Quality audits are one of the most undervalued tools for ensuring optimum product quality and on-time delivery. Importers can conduct quality audits to evaluate potential suppliers or to assess existing suppliers’ performance and progress (related: How Quality Audits Help Purchasers with Supplier Risk Management).

There are several different types of quality audits and standards, such as ISO 9001, AS9100 for the aerospace industry and ISO 13485 for medical devices. ISO 9001 quality audits are the most common for facilities manufacturing general consumer products.

ISO 9001 quality audits

ISO 9001 is a globally recognized quality management standard issued by the International Organization for Standardization (ISO).

Many foreign manufacturers are ISO 9001 certified—you’ll typically see these certifications on a supplier’s Alibaba listing page or website. Professional third-party auditing companies should also be ISO 9001 certified themselves, which will help demonstrate their ability to evaluate a supplier’s quality management systems.

But an ISO 9001 certificate alone doesn’t guarantee that the supplier actually embodies the standard’s principles in their operations. Certifications can often be falsified in China and elsewhere, and even honest suppliers sometimes lose compliance between official audits.

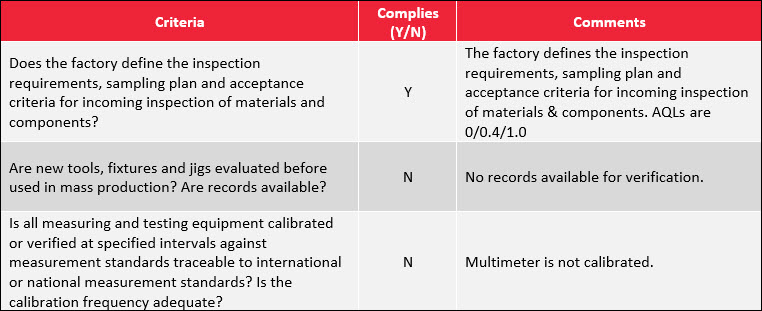

Most third-party auditing companies in Asia can perform a “supplier audit” which is usually based on ISO 9001. This audit checks the supplier’s production facilities for implementation of policies and practices compliant with ISO 9001 standards (related: 10 Factory Quality Audit Checklist Essentials).

A typical ISO 9001 quality system audit includes evaluating:

- Basic facilities, environment and equipment maintenance

- Quality management system organization

- Incoming quality controls for materials and components

- During production controls to identify quality issues

- Finished goods controls and inspection

- Lab testing capabilities

- HR recruitment and training practices

- Engineering, research and design capabilities

- Business development and management behavior

Quality audits can help you evaluate a supplier’s internal quality controls, equipment maintenance and tool verification procedures. Issues found during a quality audit can often lead to increased risk of production delays, quality defects and other production issues.

These types of quality audits might also include checking legal documents and “zero tolerance” ethical violations. But they cannot serve as a replacement for an extensive social compliance audit framework like SA8000 or SMETA.

3. Good manufacturing practices (GMP) audit

Good manufacturing audits are another type of quality audit, like ISO 9001 (related: GMP Compliance of Foreign Suppliers: The Importers Guide [eBook]). But this type of quality audit only applies to manufacturers of certain product types, which include:

- Food and beverage products

- Pharmaceuticals

- Biologics

- Veterinary products

- Medical devices; and

- Cosmetics

GMP audit standards also focus on product quality purely in relation to product safety and efficacy. This differs from ISO 9001, which focuses on the ability of a supplier to meet their customer’s requirements.

And unlike the other international audit frameworks above, GMP regulations are enforced by national agencies and governments. GMP compliance is mandatory in many markets, including the U.S., Canada, the EU and Australia.

GMP audit frameworks and requirements differ by market. If you import medical devices into both the EU and the U.S., for instance, you’ll need to conduct two separate audits of your supplier’s facility to ensure compliance with both markets’ regulations.

GMP pre-audits, or “mock audits”, conducted by a third party can help you evaluate your supplier’s compliance before an official government inspection (related: FDA Inspection Readiness: What to Expect and How to Prepare).

A GMP audit checklist should always at the very least cover the following seven factory systems:

- Organization and personnel

- Buildings and facilities

- Equipment and utensils

- Production and process controls

- Packaging and labeling

- Warehousing, storage and distribution

- Document and records control

GMP audits also vary by product type, so a GMP audit should also include specific checks tailored to the GMP regulations for your product type.

The audit checklist should be designed to reflect official government regulations and inspection requirements. Your GMP pre-audit report should clearly outline each requirement with comments on any nonconformances found.

4. Environmental audit

Environmental audits are becoming increasingly common as consumers press retailers to minimize their environmental impact (related: Fast Fashion: Good for Business, Bad for the Planet. What Can You Do?).

Environmental compliance is also becoming more important in China, as China launched a new environmental inspection scheme in 2016. These inspections have since led to the charging of officials in more than 80,000 factories with criminal offenses and fines.

Environmental audits ensure your suppliers are compliant with national and international environmental standards. An environmental audit framework typically examines the supplier’s resource consumption, pollution prevention and emergency preparedness.

ISO 14001 is the most common standard for environmental audits. But ISO 14000 certifications aren’t yet as common among Asian factories as ISO 9001. So a third-party pre-audit can help you prepare your supplier for ISO 14000 certification and identify areas for improvement.

An ISO 14001 audit evaluates the supplier’s environmental management system. This factory audit should cover the supplier’s:

- Environmental policy

- Planning for environmental impact

- Environmental management system (EMS) documentation

- EMS implementation and operation

- Monitoring of environmental impact and corrective actions

- Management reviews

With the nonconformities listed in the audit report, you can identify corrective actions your supplier should take to improve their environmental compliance.

5. C-TPAT security audit

Security audits are the least common among these five different types of audits.

Certain retailers and brands require this audit to remain compliant with Customs-Trade Partnership Against Terrorism (C-TPAT) regulations in the U.S.

C-TPAT is a public-private sector partnership program created in November 2001 to improve cargo security. The partnership focuses on protecting supply chains, identifying security gaps and implementing best security practices for preventing terrorism.

The program is voluntary, but U.S. importers, exporters, customs brokers, freight consolidators and transportation intermediaries can all join the partnership. C-TPAT members benefit from a “low risk” status and their goods are less likely to be screened at a U.S. port of entry. Some retailers might also set C-TPAT requirements for suppliers of imported goods, like CVS.

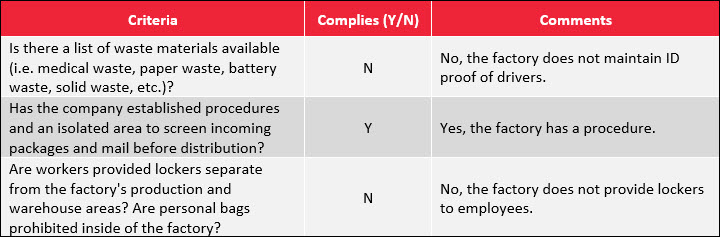

The focus of this audit is to determine the security of the manufacturing site and identify any risks for acts of terrorism associated with the facility.

A C-TPAT audit should include the following elements:

- Personnel security

- Physical security

- Physical access controls

- Procedural security

- Informational technology security – computer systems

- Security training and threat awareness

- Container security

- Supply chain security

For example, checks for the physical security of a supplier’s facility might include:

Conclusion

Whether you’re concerned with social compliance, product quality or security, factory audits can help you evaluate your supplier.

Take a close look at the requirements of the retailers and markets you sell to, your customers’ expectations and your supplier relationships. Could an audit help improve transparency into your supplier’s operations and reduce risk in your supply chain? For many importers, the answer to that question is “yes”.

Most third-party auditing companies can also prepare a corrective action plan (CAP) following an audit that outlines areas of improvement for the supplier. The CAP then helps your instruct your supplier to implement corrective actions. And later, you can conduct a follow-up audit to verify implementation.

Regularly auditing your suppliers and establishing corrective action plans is invaluable for encouraging continuous improvement at your supplier’s facilities.

Which type of factory audit do you think is most helpful in evaluating suppliers overseas? Share your experiences in the comment section below!