‘5 Essentials of a Quality Control Checklist’ eBook | InTouch

What is a quality control checklist?

Importers often want to know what is the best way to clarify their product requirements, both to their supplier and any inspection staff that might check an order before shipping.

An effective quality control (QC) checklist most often serves this purpose. A quality control checklist is basically a written guide for your products’ contents, packaging, color, barcodes, appearance, possible defects, functions and special requirements. It’s also sometimes called an “inspection criteria sheet” or inspection checklist.

Checklists for similar products often share common inspection criteria. But typically, each importer often has specific requirements for their product. That’s why it’s important for importers to tailor a quality control checklist to their unique needs.

In the rest of this eBook, learn why experienced importers rely on inspection checklists to communicate their quality standards to suppliers and QC staff, as well as what essential information you need to include in yours.

Read along, email a PDF to yourself for later by filling out the form on this page or click the links below to jump to the section that interests you most:

And learn how quality control inspectors use inspection checklists in the field by watching our video below!

Why do importers need an effective quality control checklist?

Experienced importers know that they need to provide clear product requirements to their supplier, or else they risk receiving a shipment that doesn’t meet their expectations or those of their customer. This is true whether they’re manufacturing in North America, Southeast Asia or elsewhere.

They also realize the need to provide the same requirements along with clear inspection criteria to any QC staff that will be checking the goods prior to shipping.

An effective quality control checklist addresses both product requirement and inspection criteria concerns by:

1) Outlining quality standards and product requirements the supplier is expected to meet, and

2) Providing objective criteria for inspecting the product to ensure the goods meet the customer’s expectations

Let’s say you’re importing garments from a supplier in Indonesia. That supplier can probably guess that untrimmed threads left on a garment are unsightly. But they may not realize that you have a specific tolerance for untrimmed threads.

The result is often that the supplier ships the product with an unacceptable number of untrimmed threads. And in this case, you may need to rework the goods after receiving the shipment, which may be costly and could delay distribution.

The result is often that the supplier ships the product with an unacceptable number of untrimmed threads. And in this case, you may need to rework the goods after receiving the shipment, which may be costly and could delay distribution.

The same kind of problem can result when inspection staff don’t have clear criteria for checking your product. They may report the number of untrimmed threads found in the goods they inspect, but they won’t know how many should result in a failing inspection result (related: How Product Inspectors Use Quality Control Checklists).

In both cases, you could’ve prevented these problems by providing your supplier and inspection staff with a quality control checklist clearly outlining your requirements.

⇑ Back to Top

Five key elements of an effective quality control checklist

There are five elements of a quality control checklist that are vital in making them effective. Some are more obvious to importers, while others are often unknown or neglected. The five elements include:

- Product requirements

- Packaging requirements

- On-site tests and checks

- Defect classification

- Collaboration between the importer, supplier and QC staff

Let’s take a closer look at each element and discover what problems can be avoided by including them in your checklist.

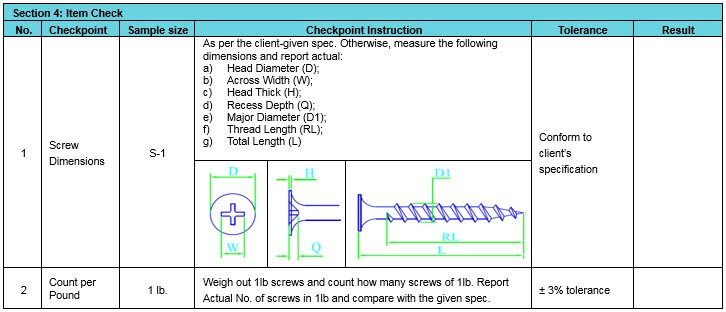

1. Product requirements

For most importers, product requirements are the most obvious point to include in their quality control checklist. And they typically spend more time specifying their requirements for the product than any other aspect of working with their supplier. Yet a large portion of inspections fail because the order doesn’t meet the importer’s product requirements.

Why is that?

One of the most common reasons for suppliers not meeting requirements is that they don’t fully understand them.

An effective QC checklist helps clear up any confusion surrounding product requirements by addressing the following:

Material and construction

If you’re importing stainless steel conduits, you might have a requirement for the thickness of zinc coating used.

If you’re manufacturing textiles, you may want a certain ratio of cotton to polyester material. And if you import injection-molded spoons, you probably want to ensure there are no sharp edges on the product.

These are just a few examples showing the need to clearly state material and construction requirements.

Weight and dimensions

Importers often state requirements for the weight and dimensions of their product in the checklist as well.

Clearly defined dimensions are especially important for manufacturers of garments, whose customers often have set fitting standards, and manufacturers of machined components, often requiring precision down to the tenth of a millimeter or smaller.

Color requirements

Color requirements for a product are typically verified by comparing a sample from mass production against an approved golden sample or Pantone color swatch.

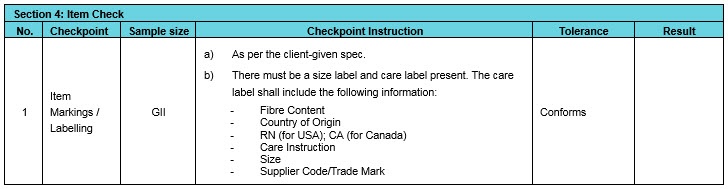

Markings and labeling

Accurate labeling is important for regulatory compliance in many industries, like clothing and electronics. Any markings and labeling on a product, such as hangtags or a CE mark, can be specified in a QC checklist and checked against your specifications.

Accurate labeling is important for regulatory compliance in many industries, like clothing and electronics. Any markings and labeling on a product, such as hangtags or a CE mark, can be specified in a QC checklist and checked against your specifications.

Some product requirements may need to be confirmed by a certified lab, while others can be checked on-site during inspection (related: What’s the Difference Between Product Testing and Product Inspection?).

But in all cases, you’ll want to include these and any others in your QC checklist. Otherwise, you run the risk of your supplier not knowing your expectations.

⇑ Back to Top

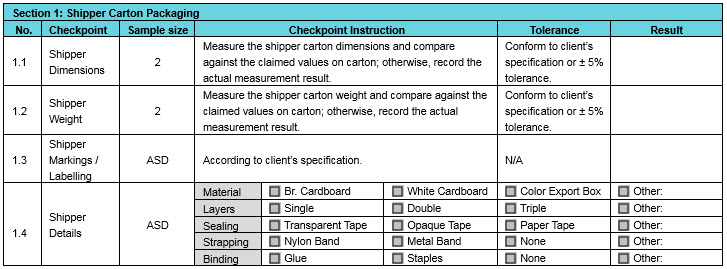

2. Packaging requirements

Besides product requirements, experienced importers are often keenly aware of their need to clarify how their products should be packaged. After all, packaging not only protects your product during transit, but is also a part of product appearance and influences consumer perception.

So it makes sense that you’d want to take care in specifying all areas of packaging, especially when manufacturing high-end or fragile goods. A quality control checklist that adequately addresses packaging requirements typically contains all of the following:

Packaging weight and dimensions

Packaging weight and dimensions can greatly affect shipping costs.

Let’s say you plan to ship 1,800 cartons of cosmetics from South Korea in a 40-ft shipping container. If the cartons are just one inch wider than your specification, you may need to rent space in a second container. What may initially seem like a small discrepancy can have a ripple effect across the entire length of your supply chain.

Carton labeling requirements

Some importers can be very particular about how their supplier labels their cartons. And you may have distributors that impose certain labeling requirements.

For example, Walmart stores and Amazon fulfillment centers, both have their own standards they expect their suppliers to meet. Requirements such as label size and contents are typical. You may also want to specify if hand-written markings are acceptable on cartons or if you require printed labels.

Packaging materials and assortment

Packaging materials and assortment method are important considerations for most importers. The way a product is packed in a carton and the materials involved can greatly influence the condition in which you receive it.

Goods produced in humid, tropical climates, like Thailand, often require packaging that’s resistant to mold and humidity. More fragile or perishable items may need to be packed with added cushioning for protection or silica desiccant packs to maintain freshness during shipping. And heavier products often need to be packed in a way that prevents the cartons from being crushed when stacked.

Retail packaging, graphics and labeling

Retail packaging specifications tend to be more important for product branding and appearance than protection, as most goods remain packed in shipper cartons during the bulk of distribution.

You’ll want to make sure your supplier adheres to your requirements for retail packaging color and labeling, especially any that relate to regulations in your market of sale. For example, certain countries often require polybags to have warning labels and small holes to prevent asphyxiation in children.

It’s essential that your QC checklist includes specifications for packaging. By setting clear packaging requirements with your supplier ahead of production, you can prevent undue damage to your product, while protecting your brand and consumers.

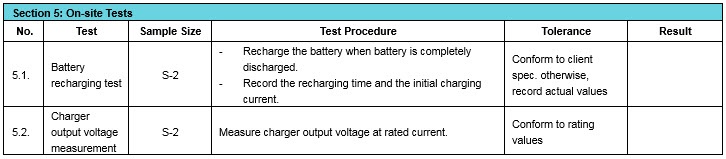

3. On-site product tests and checks

Importers often recognize the need to explicitly state requirements for their product and how they’d like it packaged. But far more importers neglect on-site product tests and checks in their quality control checklist. This is especially true of smaller companies without a dedicated quality assurance manager or someone with a similar background.

When it comes to on-site product tests and checks, consider how to address the following questions:

Which, if any, on-site product tests should QC staff conduct?

Some importers are quite familiar with the types of tests common for their product or industry, while others may not be. If you find yourself in the latter group, it pays to do some research, either by consulting an expert or by searching online for information. Either way, it’s important to know which tests you consider necessary and which can be left out during inspection.

For example, if you manufacture wristwatches with leather wristbands, you might include a crocking test in your checklist to ensure there’s no color transfer when the leather is wiped with a wet or dry cloth. But if you’re manufacturing pocket watches without wristbands, you’d probably want to omit this test because it would be irrelevant.

Besides ensuring that you’re conducting the right product tests, it’s also beneficial to avoid any unnecessary tests. On-site testing requires extra time during inspection. And if you’re paying a third-party to inspect on your behalf, this extra time can cut into time that might otherwise be spent checking a larger sample size of an order. By extension, you could also end up paying more for the service than needed.

What should be the procedure and tolerances for the product tests?

If you have an idea of the testing needed for your product, it’s also important to outline the procedure and your tolerances for the testing results because:

1.Your inspector or supplier may not be familiar with the test and

2.The procedure and result tolerances you desire for the test may not be consistent with any standard commonly used by your inspector or supplier

Let’s return again to the example of wristwatches. Watch manufacturers often make claims that their product is “water resistant” or “water proof” to a certain depth. Such claims are generally tested during inspection.

If you’re importing a watch that’s meant to be worn by scuba divers, your tolerance for water intrusion will be relatively low. And this would be reflected in the testing procedure you’d use during inspection.

Conversely, if your watches are meant to only resist water intrusions caused by accidental splashes—if they’re not even meant to be fully immersed in water at any depth during use—your tolerances for testing water resistance are likely to be much higher. In fact, you might even choose to forego water resistance testing for your product altogether.

Without clearly outlining the procedure for any on-site tests to be performed during inspection and the related pass/fail criteria, you can’t be sure that QC staff will apply the right standard for your product. The consequence is often inaccurate reporting and the need to re-inspect the product using the correct criteria.

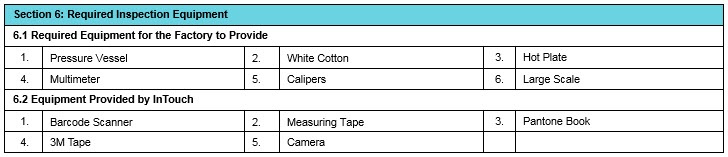

What equipment is required for the product tests?

Neglecting to specify the equipment needed for any required on-site testing is a very common mistake importers make with inspection checklists (related: 3 Mistakes Importers Make with Quality Control Checklists).

For example, if you import a fitness product that sends and stores data through an iPhone app, you’ll likely want to test this function during inspection. But if you don’t specify that an iPhone is needed for this test, there may not be one available during inspection, and QC staff won’t be able to perform the test.

Who will be responsible for providing the equipment?

Similarly, it’s also important to clearly state which party will be responsible for providing the necessary equipment for on-site product tests.

Third-party QC staff often bring a basic set of inspection tools with them to every factory visit, such as measuring tape, defect stickers and a camera. But they typically don’t bring their own hi-pot tester, environmental chamber or other equipment that’s cumbersome or expensive.

Importers largely expect the factory that’s hosting inspection to provide these types of equipment. But any assumptions you make about who will provide a moisture meter, hot plate or any other equipment could lead to a situation in which inspectors don’t have what they need to carry out your desired product testing.

That’s why it’s important that you not only address what equipment you require for testing, but also who’s expected to make that equipment available on-site.

⇑ Back to Top

4. Defect classification

When a QC professional conducts product inspection, one of the major aspects generally included in their report is any quality defects or other issues found and in what quantity.

A combination of the frequency of such issues found, their severity and the manufacturer’s tolerance of said issues are part of what determines if a product passes or fails inspection. The industry standard AQL (acceptable quality limits) uses all of these factors to deliver a clear, overall inspection result (related: The Importer’s Guide to Managing Product Quality with AQL [eBook]).

Just as it helps to clarify on-site testing, it’s also important to list any known quality issues in the QC checklist and how they should be classified in the inspection report.

Experienced inspection staff are typically aware of common quality defects for particular products. But there may be other issues you’ve experienced with the product that they haven’t seen before.  And only by explicitly noting the issues you want reported can you ensure the person checking your product will look for and document them.

And only by explicitly noting the issues you want reported can you ensure the person checking your product will look for and document them.

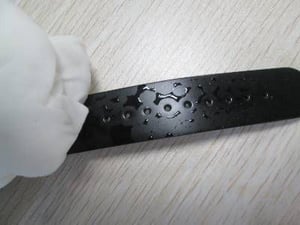

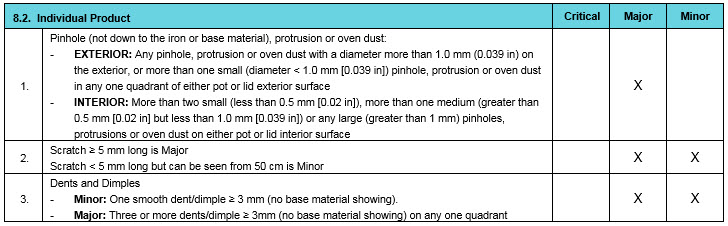

Imagine that you manufacture enamel-coated, steel cookware in China. You’ve received multiple complaints from customers about dents and pinholes in the enamel coating of a popular skillet item.

What’s the best way to address the issue? Look for it during pre-shipment inspection. And this is a good example of an issue you’d want to clearly show in your checklist so you can be confident that QC staff are vigilant about it.

Clarify how inspectors should classify and report quality defects in your QC checklist

Aside from specifying which problems to report, clarifying how inspectors should classify and report defects almost always helps you get more reliable results.

Quality defects are generally classified into one of three types, depending on severity:

1. Minor – defects found in relatively small quantities which typically don’t affect the salability of a product and aren’t normally identified by your customer.

2. Major – defects which don’t pose a threat to the safety of the user, but don’t match your specifications or golden sample.

3. Critical – defects that present a safety hazard to the user, might cause property damage or otherwise harm the end user of your product.

Importers tend to be fairly particular about how each quality defect is reported during inspection. One tablet PC importer may want a defect, such as “illegible graphics” on product packaging, to be reported as a “minor” defect. But a similar importer might have a lower tolerance for the same defect and want it reported as “major”.

How clear defect classification leads to better inspection reporting

Let’s return to the example of inspecting skillets. If you’re relying on the AQL standard, your product might fail inspection if there are either 15 minor defects, 11 major defects or one critical defect. Let’s say your inspector finds 12 instances of pinholes on different skillets he’s checked.

If you haven’t specified in your checklist that these should be reported as major defects, he might report them as minor. The result could be that the overall inspection result is “pass” when it actually should be “fail”.

Sure, by carefully looking over the report and counting the instances of pinholes reported, you might independently decide that your product has failed inspection. But inspection reports can often be quite long—sometimes dozens of pages or more for inspections covering multiple items.

Wouldn’t you prefer to be able to look quickly at the overall result near the top of the report to determine whether your supplier should ship that order? And wouldn’t the overall result be more reliable if QC staff were applying the same standard you would had you been at the factory checking the product yourself?

Including any known defects and how to classify them makes for a more effective QC checklist and leads to more transparent and informative reporting.

⇑ Back to Top

5. Collaboration between the importer, supplier and QC staff in drafting inspection checklists

When importers prepare their QC checklist, collaboration between all relevant parties is the most common element importers mistakenly leave out. And that’s unfortunate because this point is probably the most important.

Collaboration between you, your supplier and QC staff often leads to a clearer mutual understanding of product requirements, packaging requirements, on-site testing and defects (related: 4 People to Consult When Creating a Quality Manual for Your Product).

So why is collaboration key? And how does it tend to result in inspection checklists that better prevent problems?

Discuss inspection checklists with your supplier before production begins

The process of developing a QC checklist for your product should really begin as early as possible. If not during the product design phase, you should start working out inspection criteria and requirements with your supplier well before mass production begins. The reason is simple—quality is built into a product.

If you’re manufacturing leather bags and the quality of the material in the finished goods ends up being substandard, that’s not something that you or the factory can easily remedy. The product was manufactured with poor quality material. In this way, poor quality was built into the product.

If you’re manufacturing leather bags and the quality of the material in the finished goods ends up being substandard, that’s not something that you or the factory can easily remedy. The product was manufactured with poor quality material. In this way, poor quality was built into the product.

But you might prevent this by clarifying the quality level of material you require for the bags before the factory begins mass production. And collaborating with your supplier when creating the QC checklist is one of the best ways to do so.

Working with your supplier to develop inspection standards and product requirements helps you clarify expectations. In doing so, you limit the risk that your supplier will later manufacture a product that doesn’t meet your requirements.

A problem that many importers face is that their product fails inspection because they didn’t clearly communicate their quality requirements to their supplier. Your supplier might have their own quality manual, but there’s no guarantee it matches your quality standards.

Perhaps your shoe supplier is producing shoes that are the wrong size because you haven’t specified the proper measuring method. Or maybe they don’t have the necessary equipment for a particular on-site test, and you don’t find out until inspection time because you haven’t informed them that you plan to conduct that test. Worse still, you might mistakenly expect a certain component in your product, but your supplier isn’t aware that you require it.

Consequences can range from incomplete inspection to shipping delays and unsellable products. But by working with your supplier to develop your checklist, you give them the opportunity to ask questions. And you can come to an agreement about how the product will be evaluated.

Consult your QC staff on inspection methods

In the same way that feedback from your supplier helps ensure the finished goods meet expectations, feedback from QC staff helps ensure there’s a consensus on how to inspect them.

If you choose to rely on the factory’s own QC staff to inspect your product, you’ll have less opportunity to collaborate on the proper inspection method (related: Why Most Importers Don’t Rely on Factory QC Staff for Inspection). But if you’re sending someone from outside to inspect, it almost always helps to work out the procedure together with the inspector beforehand.

If you choose to rely on the factory’s own QC staff to inspect your product, you’ll have less opportunity to collaborate on the proper inspection method (related: Why Most Importers Don’t Rely on Factory QC Staff for Inspection). But if you’re sending someone from outside to inspect, it almost always helps to work out the procedure together with the inspector beforehand.

Professional QC inspectors often have the knowledge and experience to greatly contribute to whatever criteria you have for checking your product.

For example, you may not know what kind of on-site tests should be performed and what equipment is needed for a thorough inspection of the chairs you’re manufacturing in Vietnam. But the person or company that’ll be inspecting the chairs can often advise these and other important points to include in your checklist.

Likewise, if your checklist includes a test that may not be feasible or relevant to the product, the inspector can let you know.

Working with QC staff to develop your checklist helps ensure there are no surprises when inspection occurs and that you get an accurate report. It’s also one of the easiest ways you can be confident that the people inspecting your product are basically looking at it with the same pair of eyes you would.

Many third-party inspection companies will even help you develop a tailored checklist for your product (related: Create Your Own Quality Manual or Hire a QC Professional to Help?).

⇑ Back to Top

Conclusion

Now that you’ve learned about the five essential elements to include in any effective quality control checklist, how can you begin to create your own?

Effective inspection checklists should begin with collaboration. Talk with your supplier. Explain your product expectations, your desire for a thorough inspection and what aspects of the product should be checked. If possible, speak with a QC manager at the factory that’s manufacturing your product to voice any issues or quality concerns you have.

Discuss the inspection procedure with any outside QC staff that will be checking your product. Find out what industry-standard, on-site tests and checks, if any, they’d recommend conducting and on what sample size of goods.

You likely have your own quality expectations based on your product type, budget and target market. And your checklist should reflect that.

Perhaps above all else, this author hopes to stress the importance of having a thorough QC checklist that addresses all aspects of your product covered here. Remember that if you think something isn’t important enough to include in your checklist, it’s likely your supplier and any QC staff will think it’s not important enough to verify.

More quality control checklist resources

Quality control checklists are just one tool for managing product quality. Download our eBook below to find out more ways you can limit quality defects in your products!