6M’s in Six Sigma (Six Ms or 5Ms and one P or 5M1P)

In the Analyze phase of DMAIC, we want to identify the root cause of the defects that are causing variation in our process. Sometimes the culprits are easy to identify. We use the 6M’s in Six Sigma (Six Ms or 5Ms and one P or 5M1P) to help us do that. More often we have to make a hypothesis about what is causing the variation and then test that hypothesis to see if our hunch was right. But how do you come up with a hypothesis for what is causing variation?

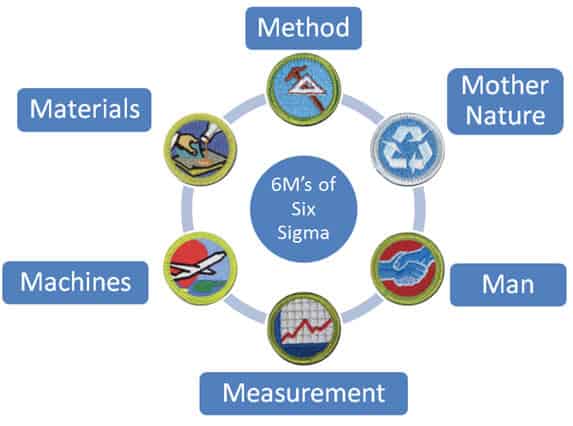

In Six Sigma we describe process variation in terms of 6M’s (aka 5 M’s and 1 P). These are six elements that contribute to variation in a process. Those six elements – 5 Ms and on P (or 6Ms) influence variation in all processes – manufacturing or not.

6M’s of Six Sigma

Ishikawa states the 6 Ms (also known as the 5 Ms and 1 P) as Man, Machine, Material, Method, Measurement, Mother Nature

- Method

- Mother Nature “Environmental”

- (Man) People

- Measurement

- Machine

- Materials

Mục lục

Let’s Takes A Look at 6M’s in Six Sigma (Six Ms or 5Ms and one P or 5M1P) Attributes

6 Ms in Manufacturing Example

- Method

- Following an assembly line is much different than a manufacturing floor that does not.

- Mother Nature “Environmental”

- Ambient humidity may cause more breakdowns in machines than normal.

- (Man) People

- Empowering any single employee to stop the entire production line if he finds a defect.

- Measurement

- If the supplier measures in English units and the manufacturer measures in metrics, issues could arise.

- Machine

- Age and robustness of the machine may impact the process.

- Materials

- Some materials are harder to work with than others.

6 Ms in Management

- Method

- If one team is developing software following a Waterfall approach while a second is using an Agile practice and a third is using Kanban, each method is different.

- Mother Nature “Environmental”

- Offices in the north are more lenient to snow days than those in the south.

- (Man) People

- People untrained in 6 Sigma tend to focus on the ‘Man’ portion of the 6Ms when looking at a process.

- A manager who is unenlightened in six sigma is most likely going to focus on Man. Unenlightened managers tend to think of the process performance as being influenced more by the person component than by the other five components of the six Ms of the machine, material, method, measurement, or mother nature. (Don’t ask whom, ask why.)

- Measurement

- It’s difficult to evaluate teams evenly if each team lead rewards their teams for different behaviors.

- Machine

- Software development productivity may be different if developers have slower machines or worse tools to use.

- Materials

- Employees can only build a product as good as the raw materials they get.

6M Insights

- When you have a bell-shaped curve, none of the 5 Ms or one P are unduly influencing the process.

- Six elements contribute to variation in a process. Those six elements – 5 Ms and on P (or 6Ms) influence variation in all processes – manufacturing or not.

- You could also use the 6M approach as a spine on each of the fishbone diagrams and then ask the 5 whys to narrow down the potential root cause.

5 m’s and one p

6M’s in Six Sigma (Six Ms or 5Ms and one P or 5M1P) Practice Questions

Unlock Additional Members-only Content!

To unlock additional content, please upgrade now to a full membership.

Upgrade to a Full Membership

If you are a member,

To unlock additional content, please upgrade now to a full membership.If you are a member, you can log in here.

Thank You for being a Member!

Here’s some of the bonus content that is only available to you as a paying member.