Basics of Supplier Quality Management: A Good Training & Book – QualityInspection.org

From time to time, I skim through a book or training that covers a topic to see if there is a new angle that we might benefit from.

This time, I picked the training entitled Seven Essentials in Supplier Quality Management by Evelyn Tan, who has 30 years of experience in consumer electronics, food, and aerospace products.

She worked at Dell for 17 years as a supplier quality manager, and for other companies such as Honeywell. She has a lot of hands-on experience. Obviously, a lot of what we do is supplier quality engineering & management, so I was curious about what she would mention as the “essentials” in that line of work.

I was not disappointed. The content is solid. It does not go much in-depth, but I would recommend it to someone starting in this field and looking for an understanding of the basics.

A practitioner writes it, and I can confirm it is very applicable for medium/high volumes of electronic production. It aligns nicely with what our best clients in that industry generally ask us to do.

Here are the 7 blocks of effective supplier quality management, according to the author:

As I wrote above, it does not go into the topics in great depth, but the author did a nice job simplifying the approach and presenting it in logical ways.

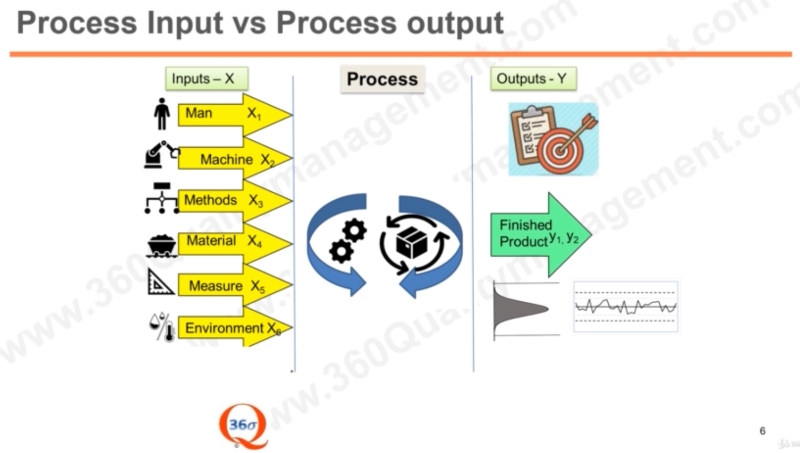

Here is an example of a slide I like. At the start of mass production of a new product, what to pay a lot of attention to?

A quality engineer should pay attention to:

- Process inputs (e.g. are people adequately trained, are machines well maintained, are work instructions well documented and followed, are incoming components up to standard, and so on)

- Process outputs (are critical to quality characteristics tightly around the target, is the proportion of products that need to be reworked/scrapped along the entire process very low, and so forth)

This is something we have been doing as part of our Production Readiness Review service, but I didn’t even think of it as “looking at inputs and outputs”. We will be adopting this view next time we provide training to the team.

*****

What about you? What training courses, or books, have you found helpful when it comes to supply quality management?

P.S.

You should read Supplier Quality Management: KPIs and Improvement Tools next, as this helps you ensure that your products are of high quality, reliability, and safety.

You can also listen to this episode of my podcast: How to Improve Product Quality from your Supplier? (6 tips) [Podcast]