COPQ (Cost of Poor Quality) in Six Sigma

Mục lục

Cost of Poor Quality (COPQ)

Six SigmaSix Sigma Definition: Six Sigma is a set of techniques and t… Learn More… Cost of Poor QualityCost of Poor Quality Cost of Poor Quality (COPQ) is a term u… Learn More… (COPQCost of Poor Quality Cost of Poor Quality (COPQ) is a term u… Learn More…) is a measure that identifies poor quality in terms of monetary value. It is always measured in money, regardless of the underlying currency.

The organization can monitor and track six sigma COPQ in a standard way across the organization. BenchmarkingBenchmarking This is a method to find the best performing sy… Learn More… COPQ values within a department against market leaders or competitive ones helps it to gaugeA measurement systems analysis (MSA) is a thorough… Learn More… its performance and determine the best target. The six sigma COPQ values can be broken down and analyzed in depth to give an indication of the areas where there are problems.

Many software and ERP packages can combine inputs to CoPQ calculation using linked processes. They can also calculate and publish CoPQ and integrate it with business results. This way, it is straightforward to measure and utilize CoPQ effectively.

How is COPQ calculated?

Technically, it is the cost incurred by the function as a result of producing defectiveDefective definition in Six Sigma: A defective unit is one t… Learn More… products. It could be that the defectA defect is a physical, functional, or aesthetic attrib… Learn More… was identified internally or externally by the customer.

Therefore:

Poor Quality = External Failure Cost and Internal Failure Cost

Let’s look at these terminologies in detail.

Internal failure cost can be a cost that is incurred due to rework, additional material procurement, over-time costs for employees to maintain delivery schedules, scrap cost, and so forth. The business type will determine which components are required.

External Failure Costs include warranty and penalty costs as well as replacement and product recall costs. They also cover transportation of stock returns and exchange goods and sales lost due stock shortages.

An intangible loss, or the loss of customer reputation and loss of market share and loyalty is even more important. Many organizations are now recognizing the relationship between Customer retention rate and CoPQ.

Phil Crosby’s book, “Quality is free”

Before we can discuss the Cost of Quality (COQ)For many years, the concept of COQ is well-known. Joseph Ju… Learn More…, or even the COPQ, it is important to understand the history of the term. Phil Crosby was one of the pioneers in quality and called his book “Quality is Free”. He once said, “Do things right the first time and you won’t have to pay to fix or redo them.”

Crosby discovered that quality-related costs can be as high at 20 percent of turnover for many organizations, while some creep up to 40 percent of total expenses. Crosby estimates that the COPQ within a successful company is between 10 and 15 percent. This is how the concepts of COQFor many years, the concept of COQ is well-known. Joseph Ju… Learn More…/COPQ were formed.

COQ vs COPQ – What is the difference?

The basic concept of quality is to provide a product or service that meets customer needs. As can be seen, COQ and COPQ can both be further broken down as they each consist of two elements.

Quality at a lower price

- Appraisal – Any activity that involves the inspection

Audits are usually performed by an audit manager. They aim t… Learn More…

- Prevention Cost – This is the cost to prevent a problem from happening. This category includes costs such as employee training, competency management and machine maintenance. Certification costs can also be included.

Low Quality at a High Cost

- External Failure This is the most serious failure. This refers to the failure of a product/service at the point of delivery or use by the customer/user. This is due to two factors. The product has been added to its full value by the producer, which includes transportation costs and storage.

- Internal Failure These are the costs associated with recognizing that a defect

Defective definition in Six Sigma: A defective unit is one t… Learn More…

Second, the reputation is damaged. The customer was the one to suffer the loss. Depending on the severity, it could cause severe damage to the reputation of the organization and possibly prevent future business. This can be especially damaging if the product is used in safety-critical applications like pharmaceutical, aerospace, medical, automotive, and medical.

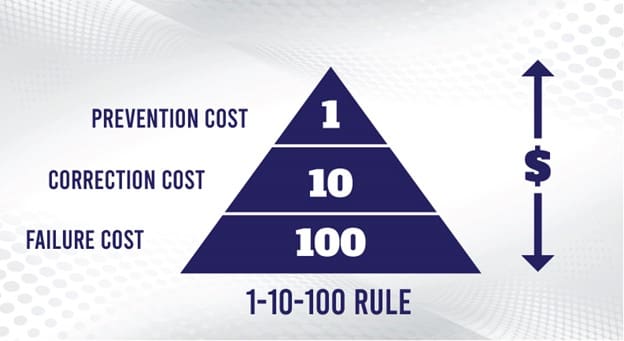

The 1-10-100 Rule

The 1-10-100 rule, a quality management model that quantifies the hidden costs of poor product quality, is used. This conceptualization model is used to give an idea of how much cost will rise as quality problems arise throughout the product’s lifecycle. The illustration below shows that a unit of prevention can save 10 units on corrective measures and 100 units on failures costs. The failure costs increase as the product moves through the various events, from design to dispatch.

What is six sigma copq in six sigma?

What is six sigma copq in six sigma?

Quality Costs

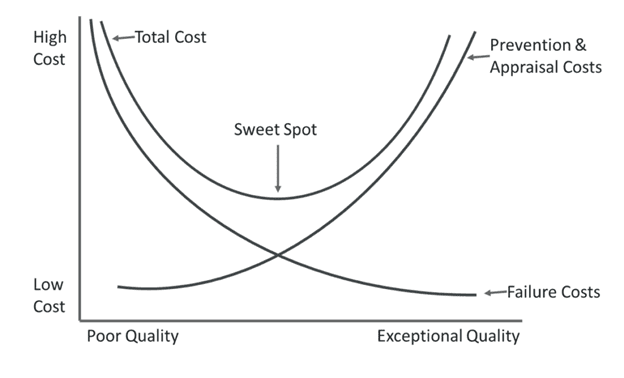

Below is the graph detailing Total Cost of QualityFor many years, the concept of COQ is well-known. Joseph Ju… Learn More…. This is a financial model of costs that are incurred to maintain and operate quality in a company. This model includes all activities that a company might perform to provide quality products and services to customers. It compares the rising costs of proactive quality management to the declining costs associated with improving the quality.

What is six sigma copq in six sigma?

What is six sigma copq in six sigma?

The economic conformance point is the lowest point on the curve (the “Sweet Spot”). This is the lowest price for quality a company can afford without causing a defect. The goal is to find a balance between the costs of preventing problems from happening and the costs of dealing with them once they do happen.

Prevention

It is a good idea to think of prevention as a positive thing. It should be viewed as an investment in high quality, rather than a cost of low quality. It is, however, a cost because we spend money on prevention. Preventive costs are actions that prevent poor quality. It’s a well-known saying that an ounce prevention is worth a thousand cures. This is how quality works.

You cannot design quality from the start. If this happens, you’ll have to check quality at the end and deal with any external or internal failure costs. Quality managers should be focusing on prevention. Quality managers tend to focus on prevention rather than correction.

What is six sigma copq in six sigma?

What is six sigma copq in six sigma?

Prevention cost examples include:

- LEAN

LEAN Definition LEAN is a production method aimed primarily … Learn More…

errorStatistics error The dual dimension of error statistics is p… Learn More…

- Plans for quality control

- Supplier evaluations

- Capability

Capability analysis is a method used to evaluate the perform… Learn More…

- Work instructions, policies, and procedures

- New product reviews

- Education, training, and quality awareness

- Failure Modes Effects Analysis (FMEA).

- Events, meetings, and projects for quality improvement

Conclusion

Philip Crosby showed how COQ can be used to increase awareness about the importance of quality, and get it discussed at the boardroom. Crosby referred to this measure as “cost of nonconformance” and suggested that organizations will make conscious choices to pay less quality if their management systems are not optimized.

A quality system must be dynamic and have an impact on the achievement of the organization’s goals and objectives. This allows you to assess the system’s effectiveness and identify problem areas and opportunities for cost reduction.

Related SSDSI Articles

IS YOUR ORGANIZATION

DEPLOYING LEAN SIX SIGMA?

THEN YOU NEED TO READ “WHY THEY FAIL”

The Author, Kevin Clay, Master Black Belt with over 20 year experience, will show you why 90% of Continuous Improvement Efforts (like Lean and Six Sigma) either Fail within 18 months.

He will show you how to quickly identify the failures and how to avoid them. If you want to build a sustainable continuous improvement culture in your organization, READ THIS BOOK!

Subscribe to our Newsletter, Download the FREE Sample and get a glimpse into the Powerful Book “WHY THEY FAIL”