Common Quality Metrics

Mục lục

Lean Six Sigma and Process Improvement Metrics Definitions

Before improving a process, it is necessary to define what is “improvement.” That definition will lead to the identification of a measurement, or metric. In other words, if you are going to play a game, you will want to know “how do you score?”

A given process may be measurable in many different ways depending on the type of data that are collected, and how the data are characterized. Variable Data may offer a much higher information content than Attribute Data. For example, the actual measured weight of an object (variable data) includes more information than merely making an attribute distinction into two categories of light or heavy.

It is often said that, “What gets measured gets done.” Measurements communicate values and priorities to an organization. Time and resources devoted to measurement demonstrate management commitment that the object of the measurement is important. Therefore, the selection of appropriate metrics is an essential starting point for process improvement.

Metrics can be organized into various operational and financial categories:

Productivity

Labor Productivity

Units Produced divided by labor hours or labor $. The labor denominator will generally include all hours worked, including overtime. To normalize this metric across different products within a plant or company, the numerator Units Produced may be calculated on an Equivalent Units basis (see below).

Equivalent Units

To aggregate Units when there is a product mix with different labor content, an Equivalent Unit factor can be calculated using the standard labor content to isolate the impact of product mix changes.

For example: An appliance plant makes refrigerators and microwaves. The standard labor content is three hours for a refrigerator, and 1 hour for a microwave. One product is picked as the baseline, and the other is expressed in equivalent units. If the refrigerator is one unit, then the microwave is 1/3 of a unit. So production of 3 refrigerators and 6 microwaves is five equivalent units.

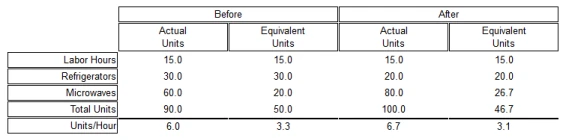

Without this equivalence, if the plant started making more microwaves (80) at the expense of refrigerators (20), and had the same 15 hours of labor, then it might appear to be more productive when it was less productive on an equivalent unit basis. As shown below, productivity measured by actual units can go up while productivity based on equivalent units can go down. Equivalent units gives a more accurate measurement of productivity improvement efforts.

Total People Productivity

This measure of productivity is similar to labor productivity but also includes salaried employees. The units numerator can be actual units or equivalent units, as discussed above, while the denominator can be hours worked or number of people (heads). Units per head is usually calculated on an annualized basis.

Sales Per Employee

Total company productivity can be measured by sales dollars (annualized) per employee.

Asset Productivity

Asset productivity can be measured by comparing units produced (actual units or equivalent units) to the net book value of property, plant & equipment plus inventory.

People

Turnover Rate

The impact of employee terminations, both voluntary and involuntary can be measured by the number of terminations divided by the average employment during the period – usually annualized.

Unplanned Absenteeism Rate

Unplanned absenteeism is the number of employees absent that were not pre-approved (vacation, pre-approved personal time, holidays, long-term medical) divided by the total number of employees.

Safety

Number of OSHA 300 Log Incidents

Any injury or illness requiring more than first-aid (e.g.,/ prescription drugs, stitches, light duty, lost time). Year-to-year comparisons should be made through a comparable time period (e.g. first 4 months of 2000 vs. first 4 months of 1999).

Number of OSHA Lost Workday Incidents

Any injury or illness resulting in light-duty or lost time. Year-to-year comparisons should be made through a comparable time period (e.g. first 4 months of 2000 vs. first 4 months of 1999).

Number of Lost Workdays

When an employee is unable to perform his “normal” job, whether it is due to light-duty or being off work. Year-to-year comparisons should be made through a comparable time period (e.g. first 4 months of 2000 vs. first 4 months of 1999).

Number of Days Off Work

The employee is unable to return to work in any capacity. Year-to-year comparisons should be made through a comparable time period (e.g. first 4 months of 2000 vs. first 4 months of 1999).

Incident Rate

Number of OSHA 300 Log Incidents x 200,000) / Number of Hours Worked

Lost Workday Illness/Injury Rate

(Number of OSHA Lost Workday Incidents x 200,000) / Number of Hours Worked

Lost Day Rate

(Number of Lost Workdays x 200,000) / Number of Hours Worked

Workers’ Compensation Cost Per Employee, or per unit (equivalent unit)

Annual cost for workers’ compensation premiums divided by the number of employees or the number of units.

Employee Experience

Average employee time on the job (or within a classification)

Assets

Total Inventory Turns

Cost of Goods Sold, annualized, divided by the average inventory level for the period tells how many times inventory turns over, or flows through the process, for a given sales volume.

Raw & WIP Inventory Turns

This is the same measure as total inventory turns, but excludes finished goods from the inventory denominator.

Days Supply of Inventory

This is the converse of Inventory Turns. Average inventory divided by Cost of Goods Sold times 365. For many inventory reduction initiatives, inventory may be measured in physical terms, such as the number of bins of parts, and equated to days consumption, rather than valuing the inventory. This is a quicker, more visible, and more easily understood measure for shop floor projects.

Total Cycle Time

Total time to complete a physical process, including wait time and inventory time. Also known as Dock to Dock Time. For example: Raw material is received and is consumed over 15 days and the manufacturing process takes 7 days, including time spent in buffer inventories. Total cycle time is therefore 22 days. The definition can be broadened to include finished goods.

Value Added Cycle Time

Portion of the total cycle time where value is actually added to the product or service – excludes all wait time and transit time through a plant.

Cash Conversion Cycle (Dell) – CCC = DSO + DSI – DPO

Days Sales Outstanding plus Days Supply in Inventory minus Days of Payables Outstanding. This metric shows how fast purchased materials and other inputs are turned into cash vs. how quickly cash is disbursed to pay for those materials and inputs.

Quality

Cp

Cp is a measure of potential process capability. It is the ratio of the six-sigma spread of a process distribution to the tolerance of that distribution. The process must be normally distributed and stable in order to assess Cp. Cp gives the maximum process capability (Cpk) if the process is centered exactly in the middle of the tolerance.

Cpk

Cpk is a measure of the actual process capability. It is calculated by dividing the distance of the process mean to the nearest tolerance limit by 3 standard deviations of the process. Again, the process must be normally distributed and stable before assessing Cpk. See the Statistical Process Control section of the Toolbox for additional help on this subject.

First Pass Yield

Percentage of units that meet specifications without any rework or repair. This is a commonly used measurement, but has dubious value for two reasons: A) rework and repair is often “hidden” – takes place up the line but is not recorded, and B) multiple defects occurring on a single unit are not captured.

Defects Per Unit

Total number of defects identified on all units divided by the number of units. This metric gives a better measure of quality than First Pass Yield because it captures all defects. Care must be taken to capture “hidden” rework and repairs that may take place up the line or prior to the reporting point. This metric is also more readily convertible to Defects Per Million Opportunities for Six Sigma projects.

Defects Per Million Opportunities (DPMO)

This is a primary Six Sigma metric. Defects per opportunity is used instead of defects per unit to facilitate more direct comparisons between processes with varying levels of complexity. Assembling an automobile is far more complex than manufacturing a patio stone, with far more opportunities for error, so defects per unit is a poor basis for comparing the capability of the manufacturing process.

Defects are a failure of the process to meet a “Critical to Quality Characteristic” – that is to say, a characteristic that customers care about. The number of opportunities must be determined based upon these “Critical to Quality Characteristics”, and should be based upon a well-reasoned process. Inflating the number of opportunities will lower the ratio of defects to opportunities, and bias the sigma level upward. At the level of 3 defects per million opportunities, the process is said to have achieved Six Sigma status.

An important point to remember when working with DPMO is that customers don’t buy opportunities, they buy units. Furthermore, all defects are not created equal, even if they are important to customers. For example, customers care about paint flaws on a car, but they care a lot more about a defect that causes the car not to start. Accordingly, it may be useful to categorize defects into different categories by process and assess the Six Sigma level of each process (e.g., Paint vs. Ignition System).

Fill Rate

Percentage of units ordered that are shipped on a given order. If an order for 10 widgets and 10 sprockets is filled, but only 9 of the widgets are shipped due to a product shortage, then the fill rate is 95%.

Line Item Fill Rate

Percentage of line items, or SKU’s, that are shipped on a given order. If an order for 10 widgets and 10 sprockets is filled, but only 9 of the widgets are shipped due to a product shortage, then the line item fill rate is 50%, because only one of the two line items (SKU’s) was shipped 100% complete.

Shipment On-Time %

Percent of shipments made on or before the due date.

Shipping Errors Per Shipment

Total number of shipping errors (by line item) for a period divided by the number of shipments made during that same period.

Warranty Percent of Sales

Warranty dollars paid during a period divided by the net sales for that same period.

Warranty Claims per Unit

Total number of warranty claims (not dollars) received during a period divided by the number of units sold during the same period.

Survey Complaints (TGW’s) per Unit (or per 1000)

The number of complaints, or “Things Gone Wrong” reported on a customer survey, divided by the total number of units included in the survey responses. This metric may also be expressed as complaints per 100 units, 1000 units, or even 1,000,000 units.

Customer Satisfaction

Customer Satisfaction may be measured directly by survey and expressed as a percentage, such as Percent of Customers Completely Satisfied.

Total Productivity Maintenance

MTTR

Mean Time to Repair

MTBF

Mean Time Between Failure

Operational Effectiveness Rate (OEE)

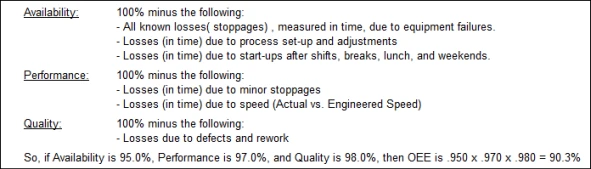

OEE is a combined metric that shows the impact of equipment availability, equipment performance, and quality of output. The metric is calculated by multiplying Availability x Performance x Quality, as detailed below:

Uptime

100% minus losses for all causes, including equipment failures, set-ups, adjustments, start-ups, and stoppages. Uptime does not measure actual speed vs. engineered speed.

Preventive Maintenance %

Proportion of total maintenance time spent on preventive actions vs unplanned actions.

How Can You Learn More?

Looking for more definitions and examples? Then check out SigmaPedia, the online Lean Six Sigma and process improvement encyclopedia!

VISIT SIGMAPEDIA