Cost of Quality

Mục lục

Cost of Quality Definition

Cost of Quality can be termed as the process that measures and determines where and how organizations’ resources are utilized to maintain quality and prevent poor outputs. It can be regarded as a method of process improvement and quality assurance and prevents internal and external audit failures.

Explanation

You are free to use this image on your website, templates, etc., Please provide us with an attribution linkHow to Provide Attribution?Article Link to be Hyperlinked

For eg:

Source: Cost of Quality (wallstreetmojo.com)

Components

There are four broad components: prevention costs, internal failure costs, external failure costs, and appraisal costs.

You are free to use this image on your website, templates, etc., Please provide us with an attribution linkHow to Provide Attribution?Article Link to be Hyperlinked

For eg:

Source: Cost of Quality (wallstreetmojo.com)

#1 – Prevention Costs

The prevention costs can be regarded as the costs the business incurs to reduce and minimize defects. The prevention costs are determined at the start of every new process step. The prevention costs are highly regarded as saving organized labor and manufacturing costs. If the business does not undertake the prevention costs, it could result in high defect costs at a later stage, which could prove to be expensive for the business.

#2 – Appraisal Costs

The appraisal costsAppraisal CostsAppraisal costs refer to the expenses incurred on the quality control and check by the organization. It determines that the product or service fulfills the customer expectations, are non-defective and comply with the regulatory norms.read more can be regarded as the costs that the business incurs when it works towards identifying defective items. It is done before any product has to be shipped to the end consumer. The quality checks professional inspect finished goods in the process inventory and raw materials.

#3 – Internal Failure

Internal failure costs are the cost that the business or corporate entity has to bear once the defective items are identified before proceeding with the shipment. These costs signify the direct materialDirect MaterialDirect materials are raw materials that are directly used in the manufacturing process of a company’s goods and/or services and are an essential component of the finished goods manufactured.read more, manufacturing overhead, and direct labor consumed by each defective item.

#4 – External Failure

The external failure costs are costs the business has to bear on account of defective items shipped to the customers. These costs are often regarded as expensive as they would cause the business to incur high warranty and return costs along with already incurred manufacturing overheadsManufacturing OverheadsManufacturing Overhead is the total of all the indirect costs involved in manufacturing a product like Property Tax on the production premise, Remunerations of maintenance personnel, Rent of the manufacturing building, etc. read more.

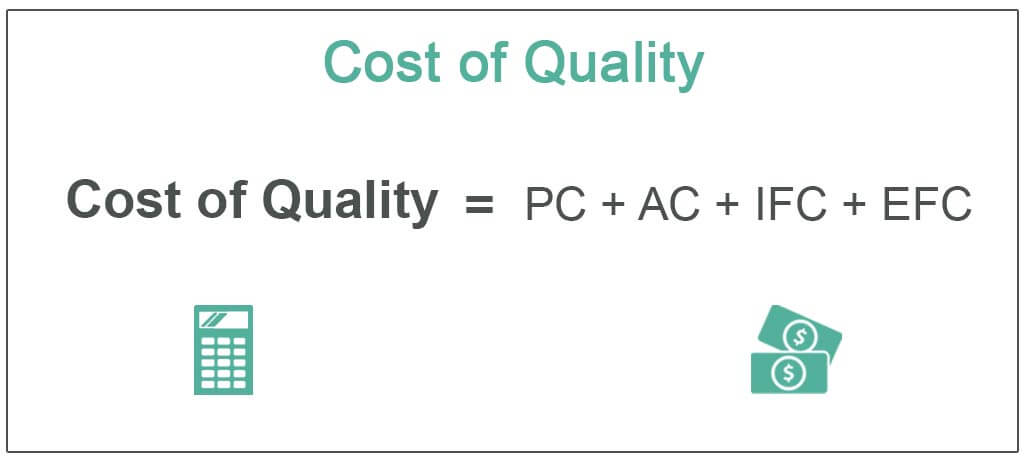

Cost of Quality Formula

Cost of quality = CoGQ + CoPQ

It can further be expressed as displayed below: –

Cost of Quality = P C + A C + IFC + EFC

Here,

- The cost of good quality is represented as CoGQ.

- The cost of poor quality is represented as CoPQ.

- The prevention cost is represented as a PC.

- AC represents the appraisal costs;

- IFC represents the internal failure costs.

- EFC represents the external failure costs.

Example of Cost of Quality

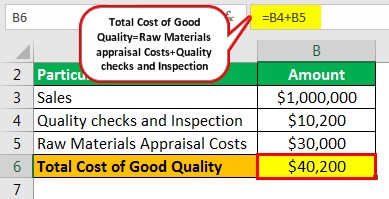

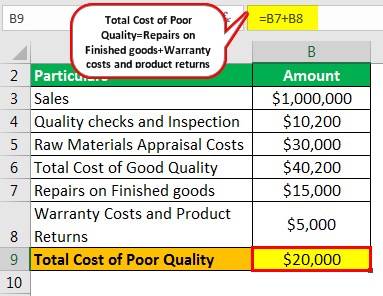

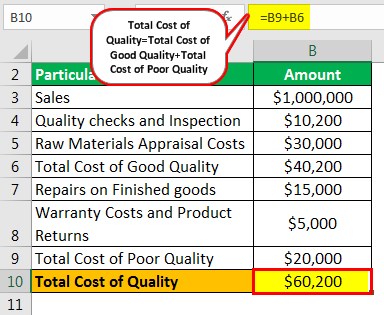

Let us take the example of a business that generates $1,000,000 in sales. It incurs $10,200 in Quality checks and inspections. It pays $30,000 for appraising the purchased raw materials. Additionally, it pays $15,000 for repairs on finished items. It maintains a provision of $5,000 for warranty costs and product returns. Help the management determine the cost of quality as a percentage of sales.

Solution:

Step 1: Calculation of Total CoGQ

=$10200+$30000

=$40200

Step 2: Calculation of Total CoPQ

=$15000+$5000

=$20000

Step 3: Calculation of Total CoQ

=$20000+$40200

=$60200

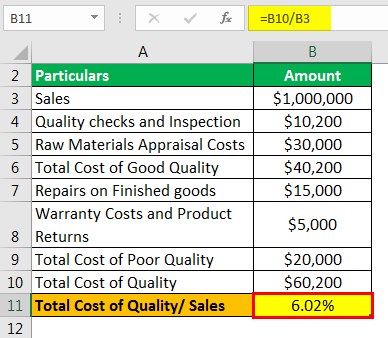

Step 4: Calculation of cost of quality as the percentage of sales

=$60200/$1000000

=6.02%

The inspection checks and appraisal costs on raw materials account for the CoGQ. The costs of repairs, warranty, and product returns account for the CoPQ.

Why Measure the Cost of Quality?

The determination of the cost of quality remains to be critical and varies for different organizations. If this cost is not measured and quantified, the organizations working in the competitive industries would never gain the upper hand and survive the ever-changing dynamic environment. Therefore, measuring it is necessary as it helps the business maintain a healthy and positive bottom line.

Goal

- It helps the organization to chalk out wrong and poor-quality output.

- It helps in problem-solving, wherein it performs cost and benefits analysis on quality and process improvement initiatives.

- The model or cost of quality helps in a single-point evaluation of quality performance.

- It further evaluates the costs of failures and appraises them accordingly.

Importance

It is a fundamental methodology as it allows the business to derive a competitive edge over its peers working in the industry. These costs ensure that problems and root causes that can impact the business are identified very early, and preventive actions can be undertaken.

It also helps the organization devise and determine the corrective actions for any potential failures. It usually happens when an organization identifies defective products before and after shipping to the customers.

Difference Between Cost of Quality and Cost of Poor Quality

- The cost of poor quality (CoPQ) is a subset of the cost of quality.

- The CoPQ is the business cost incurred when the defective products are identified before and after shipping to customers.

- Therefore, the sum of internal and external failure costs can be termed the CoPQ.

- The CoPQ usually consists of product return costs and warranty costs related to the products.

- On the other hand, the cost of quality is determined by the CoGQ and CoPQ.

- It is determined as the sum of the cost of good quality and poor quality.

- The cost of quality takes into account prevention costs, appraisal costs, internal failure costs, and external failure costs.

- The prevention and appraisal costs do not constitute the CoPQ as such costs attempt to identify defective products at the beginning of the production process.

- The CoPQ arises after the end of the production process and on defective finished goods.

Benefits

The cost of quality helps the business derive a competitive edge over its peers working in the industry. It allows the organization to plan for costs that the business has to incur in maintaining quality costs and helps the organization make provisions over them, which helps the organization maintain a favorable bottom line.

Conclusion

The cost of quality can be termed as the costs the business has to bear to utilize its resources to maintain qualitative outputs to its targeted customers. If the business does not employ its resources to adhere to quality metrics, it will lose out on its competitive advantage. Furthermore, if the cost of quality is not incorporated, it can severely impact the business’s bottom line.

Recommended Articles

This article has guided the Cost of Quality and its definition. Here we discuss components, goals of cost of quality along with its formula, examples, and differences from the cost of poor quality. You can learn more about financial analysis from the following articles –