The 5 M’s of Kaizen for Managers

We often describe Kaizen as a way of looking at the world rather than a prescription for how to achieve positive change. Kaizen thinkers seek to make small changes to operations daily in search of higher quality, more efficiency, and less waste. But because the concept of Kaizen is so philosophical, it can be a challenge for people new to the idea to understand what it means in practical terms.

Related: What is Kaizen?

One useful tool for training managers to adopt the Kaizen mindset is called the 5 M’s. By consistently examining the 5 M’s, managers will be able to recognize when something in a process is not working and improve efficiency and profitability. This model can be used for risk mitigation, addressing safety issues, and improving quality. It can be used right alongside other Kaizen techniques such as the 5 Whys, 5S, and Gemba walks.

The 5 M’s are:

1. Manpower

The heart of Kaizen is respect for people. It is the responsibility of managers to engage employees in continuous improvement. They must constantly seek feedback and create opportunities for thoughtful changes to process standards. As Taiichi Ohno, the father of the Toyota Production System, said, “Standards should not be forced down from above but rather set by the production workers themselves.”

It is also essential that managers recognize and reward those who are contributing to positive change. In fact, improvement should be a key component of employee goals and performance management.

2. Machines (Equipment, Technology)

The need for managers to understand the operation of each piece of equipment and tool in a manufacturing plant is obvious, but technology plays an important role in other sectors as well. In a hospital, for example, “machines” might include medical equipment and electronic health records and other software applications. Whether it’s a physical machine or a software application, managers must ensure that it works as expected and that use of the technology is achieving the desired goal.

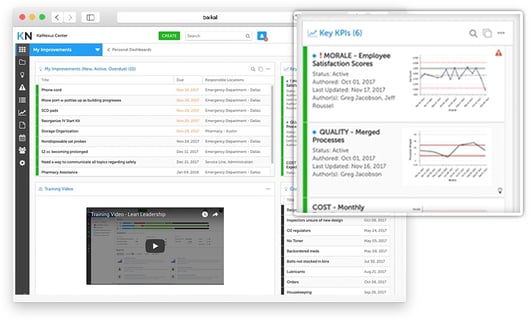

Another element of technology in the practice of Kaizen is software designed to support continuous improvement. Kaizen software solutions create a platform for employees to suggest opportunities for improvement and managers to guide the selected changes through the process of finding and implementing solutions.

3. Materials

The flow of materials is an important element of Kaizen. In an effort to eliminate excess inventory, a just-in-time model is adopted to chart how materials should flow in a process. Only necessary materials are in the work area. This applies to information work as well as a factory line. For example, new code should not be passed along to a QA department that does not have the current capacity to test it. In healthcare, rarely needed supplies should not be stocked in patient care areas.

Related: Digital Kanban Boards

4. Methods

Helping processes operators develop standard methods is the foundation upon which Kaizen happens. In the words of Ohno, “Without standards, there can be no improvement.”

Once the best practice for a process is developed and implemented, managers can coach employees on doing their work correctly. Standard work documentation should be made available in the place where work is done and include any useful charts, images, or other assets.

Of course, the standard, while rigorously followed, is not set in stone. Managers lead employees though an improvement cycle whenever an opportunity for improvement is uncovered. A new standard is developed and maintained until the next opportunity comes along.

5. Measurements

In order to know if a process is running smoothly, managers need a set of performance indicators to measure. Not only will they help identify process breakdowns, but they also form the baseline from which improvement can be measured. The most effective measurement tools are visual. People can instantly see when there is an interruption in flow, a definition from typical results, or a task that has not been completed on schedule.

Related: An Introduction to Process Control Charts

Breaking Kaizen down into the 5 M’s gives managers clear areas of focus for improvement. If you have engaged people, effective technology, a smooth flow of materials, standardized methods, and visual measurement tools, you’ll be well-positioned for success.