Cost of Poor Quality (COPQ): Why Is It Critical? Can AR help? – Plutomen

Enterprises focus on providing the best quality products at the lowest prices possible to their customers. The aim is to remain profitable while creating a loyal customer base. On the journey to being profitable, it is imperative to understand the actual cost of poor quality (COPQ).

What is the Cost of Poor Quality?

Poor quality costs the organization money and time. It affects not only the company’s reputation but also its bottom line. Poor quality leads to lower customer satisfaction, higher costs for rework, and lower revenues. Due to this, more time is spent on fixing issues with the product or service instead of creating new ones. Poor quality can result from a lack of focus, understanding, or even resources.

Most enterprises have quality-related costs as high as 15-20% of their sales revenue. The costs may go as high as 40% of their total operations for some of them.

The Cost of Quality (COQ) is a methodology that allows an organization to determine which of its resources can be used for preventing poor quality.

Cost Of Poor Quality Includes:

-

Appraisal costs like verification, quality audits, and supplier ratings.

-

Internal failure cost like Waste, Scrap, Rework, rectification & failure analysis

-

External failure costs like repairs, servicing, warranty claims, complaints, and returns.

-

Prevention costs like quality planning, quality assurance, training, and more.

Calculating the Cost of Quality can be a bit tricky. It includes multiple parameters, and there are high chances of error when calculated by humans. Fortunately, due to advancements in technology, we have advanced approaches to analyzing expenses and quality problems landscape.

How To Calculate Poor Quality Costs In Manufacturing?

The cost of quality is calculated based on two essential components- Cost of poor quality and cost of good quality. The cost of good quality in the manufacturing business is a set of practices designed to ensure that the quality of products and services is high. A poor-quality problem triggers enterprises to invest in systems that ensure high quality.

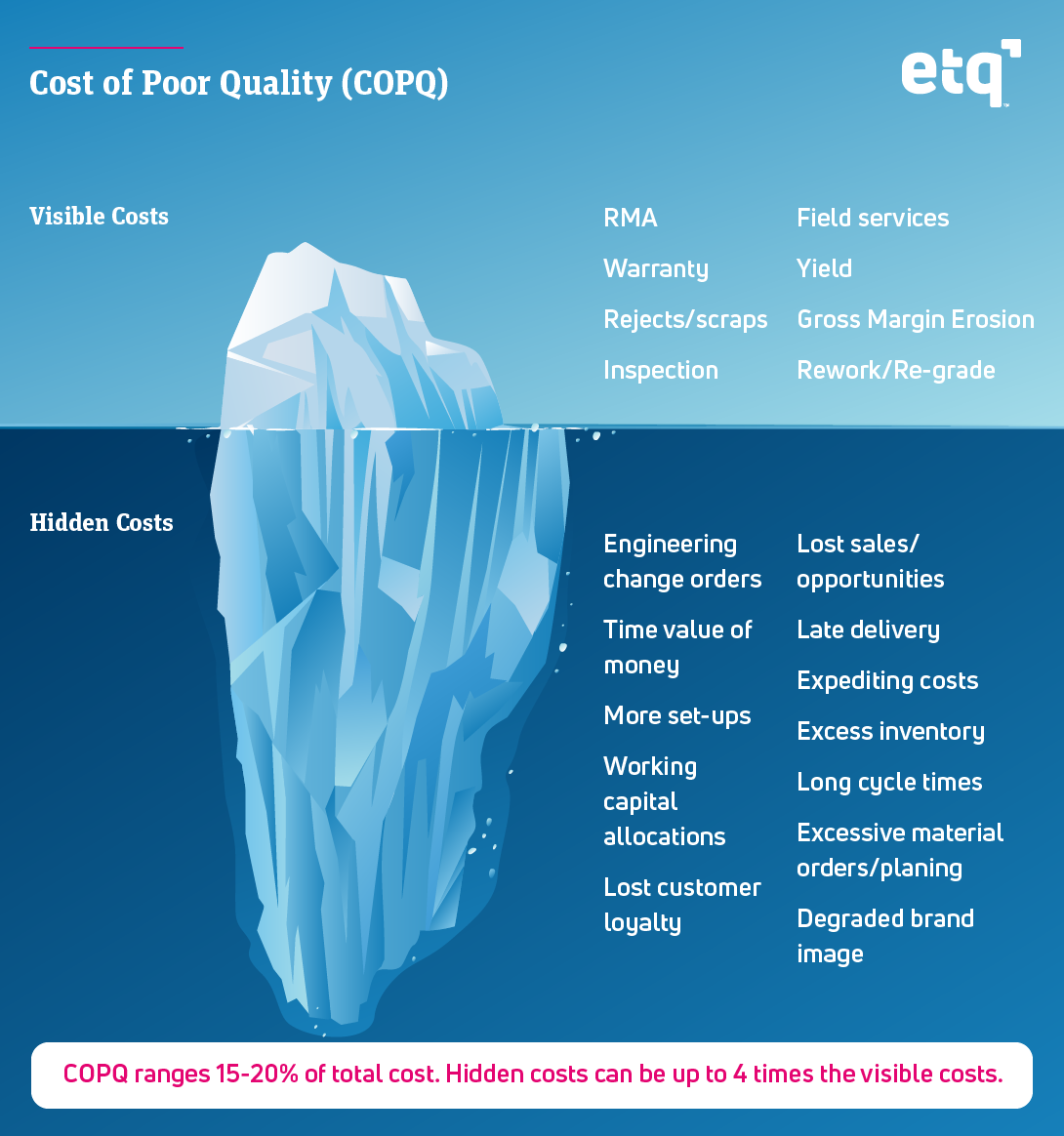

Image Credit:

etq

There are many components of the cost related to low quality. Here, we’ve listed some easily noticeable cost areas:

-

Scraps and rework

-

Resource used for rework and scrap

-

Wasted time on manufacturing low-quality products

-

Energy wasted on unusable materials

-

Materials used in scrap

-

Warranty claims

-

Customer fines

-

New product and delivery costs for replacements

These are just a portion of the actual poor-quality cost. There are many other losses like:

-

Planning delays

-

Replanning for scrap and rework

-

Overtime by employees for meeting deadlines

-

Time lost on identifying root causes

-

Time spent on correcting and preventing plans to prevent low-quality problems from happening again

-

Time, money, and energy are spent on marketing to regain brand image and restore trust in the brand

These are the costs manufacturing industries pay for low quality. The cost of low quality cannot be calculated by operations or finance staff alone. They must work together to calculate it.

What Is An Advanced Manufacturing Approach To Minimize Quality Issues?

Once you calculate the cost of poor quality, it is necessary to take actions that minimize quality issues and provide a high-quality manufacturing environment. Advanced manufacturing approaches can help you spot patterns in systems and can help you to avoid problems.

How To Avoid Quality Problems With Advanced Manufacturing?

Quality problems often arise due to a lack of proper communication. Most production processes are interdependent, and a small error in a single process can result in quality problems. It is essential to fill this communication gap between the processes. Improving this will help businesses lower the cost of poor quality.

One way to improve it is by using Augmented Reality. AR can provide a new way to communicate and collaborate in real-time. It can also be used as a means of communication between two processes that are not in the line of sight of each other. AR is used to provide instructions regarding different processes like how to assemble a product. The instructions are not only available in a manual or video but can overlay on the machine itself.

The workers can pass instructions at the previous step to upstream works to understand the previous process and prepare accordingly for the next one. It can also be recorded and stored on the cloud, so whenever a shift changes, the workers can get a detailed view of what was done by the previous staff and prepare themselves for the upcoming tasks.

How To Spot Quality Patterns With Advanced Manufacturing?

Spotting quality patterns is another way to avoid the production of low-quality products. A specific pattern is pre-built by manufacturing industries for the production of different products. When these patterns are monitored closely and, data is collected at every data point, it provides a detailed view of where things are going wrong.

IoT devices can be used to gather and analyze data to spot patterns. Spotting quality patterns has become easier since manufacturing companies started using IoT devices. The increased use of IoT has led to various benefits such as better production efficiency, reduced defects and errors, improved customer experience, and more competitive pricing.

When combined with Artificial intelligence and machine learning, these IoT devices can help predict the problems that may arise in the future. Using these predictions, companies can take proactive steps to train employees, manage materials, and timely maintenance and repairs can help companies solve quality problems.

AR Role In Manufacturing

The use of AR in the manufacturing industry has increased over the years. The technology is used for production, training, quality control, and maintenance purposes. AR has been used to help make complex tasks easier and reduce the cost of producing poor-quality products.

Using AR devices has reduced Boeing’s wire assembly process time by 25% and has lowered errors to nearly 0%.

Lowering The Cost Of Poor Quality With AR

To lower the cost of poor quality, everyone on the production line must have enough information on what’s been happening in the previous step and shifts. In manufacturing sectors, AR is used to help workers get details of the products in the production line. They can check the history associated with the product, like updates or maintenance as well.

AR is used to train workers to use equipment in the production process by creating real-life virtual scenarios. This can be done through optical devices, such as a head-mounted display, or other means, such as a printed page or computer screen.

AR can be used to help workers with work instructions on the shop floor before they begin their shifts. Some factories use AR glasses to provide instructions to workers on how to assemble parts and machines. This way, they can avoid errors that would have been made if they were assembling without the help of AR glasses. It will help them lower the chances of defective products, which ultimately reduces the cost of poor quality.

AR helps designers to create high-quality products by giving them all the information they need in one place. They can see how their product would look in different settings with different people using it. AR can help designers see how the product will look in real life and make changes accordingly. They can collaborate with experts when assistance or suggestions are needed. AR also helps with a rework that needs to be done to ensure product quality.

Conclusion

With the increasing demand, the manufacturing industry is growing at a rapid pace. With all the technology in place, the manufacturing industry can leverage them to lower the cost of poor quality. Augmented reality can play a significant role in reducing the cost of poor quality. It can help reduce the cost of poor quality by giving workers the ability to see a detailed view of the process and training them to be more efficient at work. The use of AR combined with IoT devices in the manufacturing industry will be a promising solution to the problem of poor quality.

Implementing a customized AR solution at your manufacturing facility is not a challenge with the support of an experienced partner. With more than 8+ years of experience in servicing and consulting clients in AR. Plutomen offers the much-needed expertise for deploying AR solutions for B2B enterprises. Plutomen is an Augmented Reality based SaaS platform that provides AR solutions to industrial enterprises to simplify their digital transformation. We help enhance frontline capacities by self-assisting resources and digitized workflows and connecting them with remote collaboration experts.

Wondering how AR will contribute to improving production quality at your manufacturing facility? Book a demo today to understand from an expert.