Quality Function Deployment – ppt download

Presentation on theme: “Quality Function Deployment”— Presentation transcript:

1

Quality Function Deployment

2

Objective of the Presentation

Present the concepts and elements of the Quality Function Deployment (QFD) techniques. Highlight the application of QFD in various areas. Explore the possibility of using it in designing YR inventory system.

3

Presentation Plan Introduction Quality Function Deployment (QFD)

The QFD Process Advantages of QFD Applications of QFD Applying QFD to YR inventory system.

4

Introduction QFD is a planning technique that is born in Japan as a strategy for assuring that quality is built into new processes or systems design. It helps organization to take the voice of the customer and factor their wants and needs into organization product and process planning

5

Introduction Yoji Akao is widely regarded as the father of QFD and his work led to its first implementation at the Mitsubishi Heavy Industries Kobe Shipyard in The interest in QFD in the West was stimulated by reports of the achievements made by Toyota through its application between 1977 and These included a reduction in product development costs by 61%, a decrease in the development cycle by one third and the virtual elimination of rust related warranty problems

6

QFD Definition Yoji Akao defined QFD as “a method for developing a design quality aimed at satisfying the consumer and then translating the consumer’s demands into design targets and major quality assurance points to be used throughout the production phase”.

7

Quality Function Deployment

QFD is a TQM tool. It is a planning technique that was born in Japan as a strategy for assuring that quality is built into new processes. The QFD process uses matrices (sometimes called quality tables) to help organizations to satisfy their customer requirements, e.g. House of Quality (HOQ). These matrices are developed to generate design concepts, evaluate them and propose process parameters to deliver or produce the best design concept that meets customer requirements

8

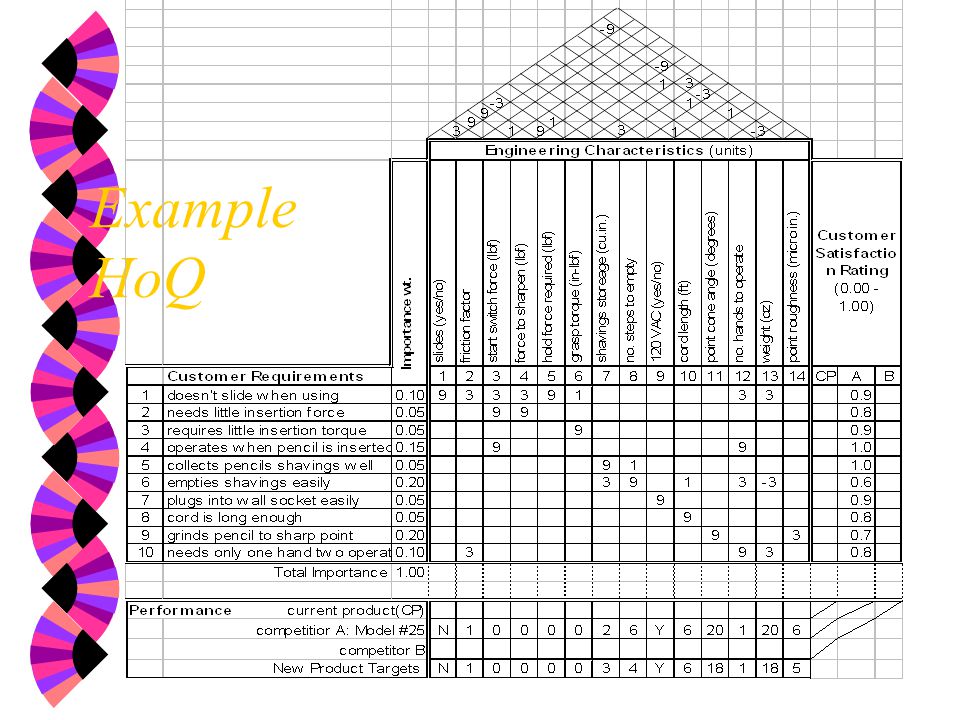

The house of Quality The “House of Quality” matrix is the most recognized form of QFD. It is utilized by a multidisciplinary team to translate a set of customer requirements, drawing upon market research and benchmarking data, into an appropriate number of prioritized engineering targets to be met by a new product design. There are many slightly different forms of this matrix and this ability to be adapted to the requirements of a particular problem or group of users forms one of its major strengths. The general format of the “House of Quality” is made up of six major components which are completed in the course of a QFD project

9

Example HoQ

10

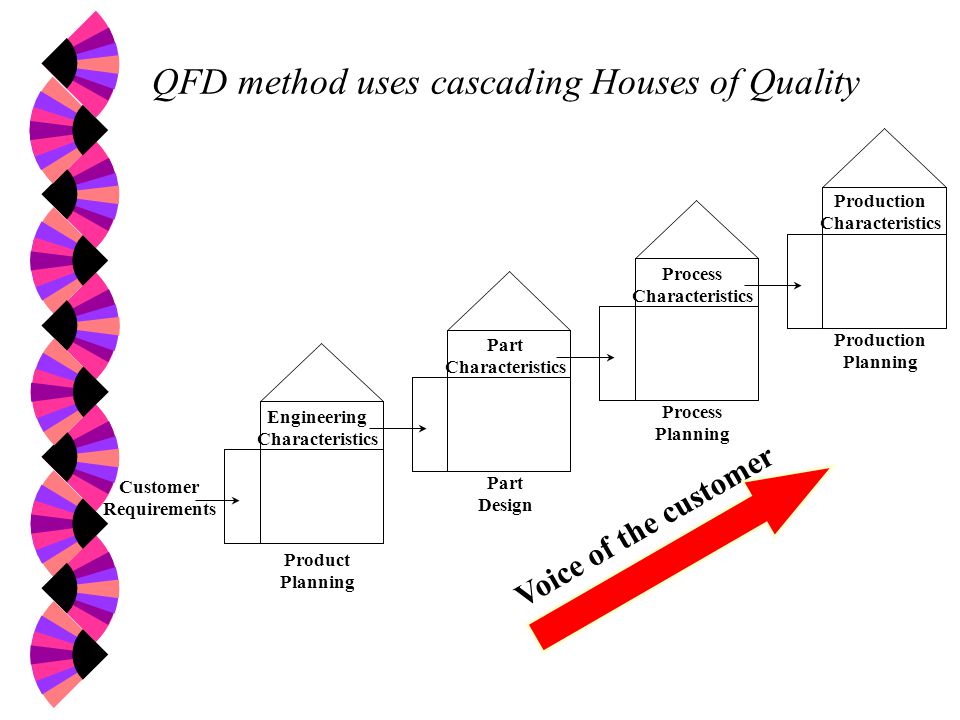

QFD method uses cascading Houses of Quality

Customer Requirements Part Characteristics Engineering Process Product Planning Design Production Voice of the customer

11

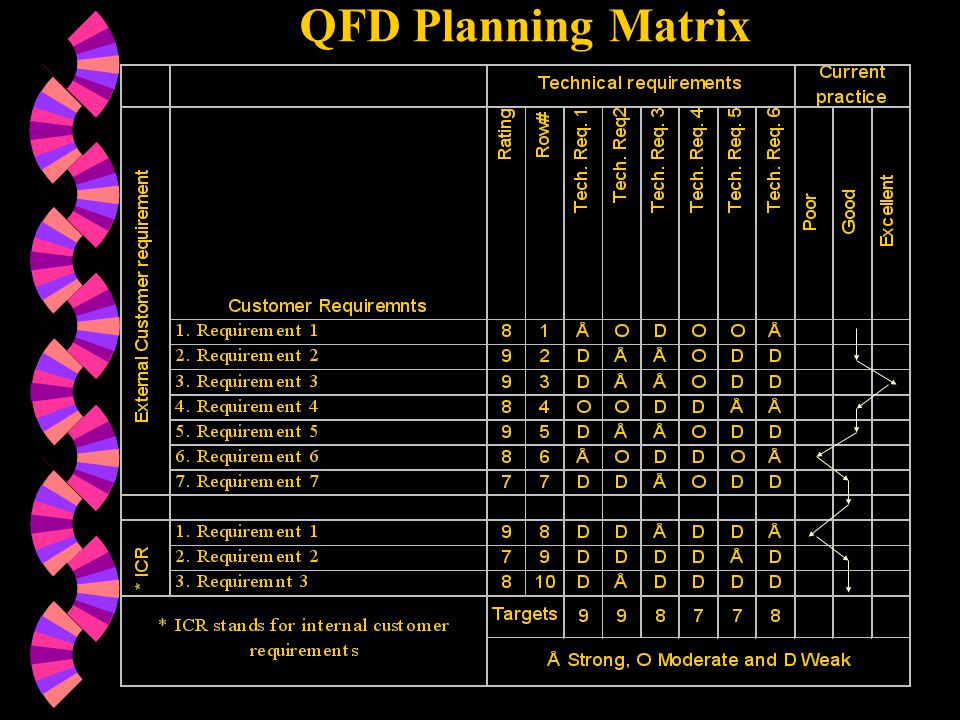

The QFD Process The QFD process uses matrices to help the organization to satisfy their customer requirements ( which are a structured list of requirements derived from customer statements). The first of these matrices is called the house of quality (HOQ). It displays the customer wants and needs along the left side of the matrix and the technical requirement (which are a structured set of relevant and measurable product characteristics )to meet these wants along the top of the matrix

12

The QFD Process The HOQ has several sub-matrices joined together and they relate technical requirements and technical targets to customer needs. Then a series of matrices is generated to address the whats (customer needs) with the Hows ( possible technical Know-how) . Other matrices are developed to generate design concepts, evaluate them and propose process parameter to deliver or produce the best design.

13

Advantages Reduced time to market Reduction in design changes

Decreased design and manufacturing costs Improved quality Increased customer satisfaction

14

QFD Resources The U.S. institute dedicated to the advancement of Quality Function Deployment. The institute organizes forums and seminars, holds an annual symposium to publicize the latest QFD applications and administers the Akao Prize. The International Council for QFD (ICQFD) aims to promote a united international effort in the development of QFD techniques. The council organizes international conferences on QFD and promotes QFD research.

15

Application Of QFD Some of the application of QFD are:

Production/Manufacturing Maintenance Design courses and curriculum Design of performance measures Aerospace

16

Applying QFD to an inventory system

Identify the customer requirements (external and internal). Identify the technical requirements. Use the house of quality matrix to relate customer requirements to technical requirements.

17

Customer requirements

The customer requirements are collected through a carefully designed survey. Focused interviews.

18

Information source Surveys Market Studies Literature Focus Groups

Observation Studies Benchmark Studies

19

Technical Requirements

The technical requirements are obtained from the inventory elements that are essential for the design of the inventory system. The literature on inventory systems.

20

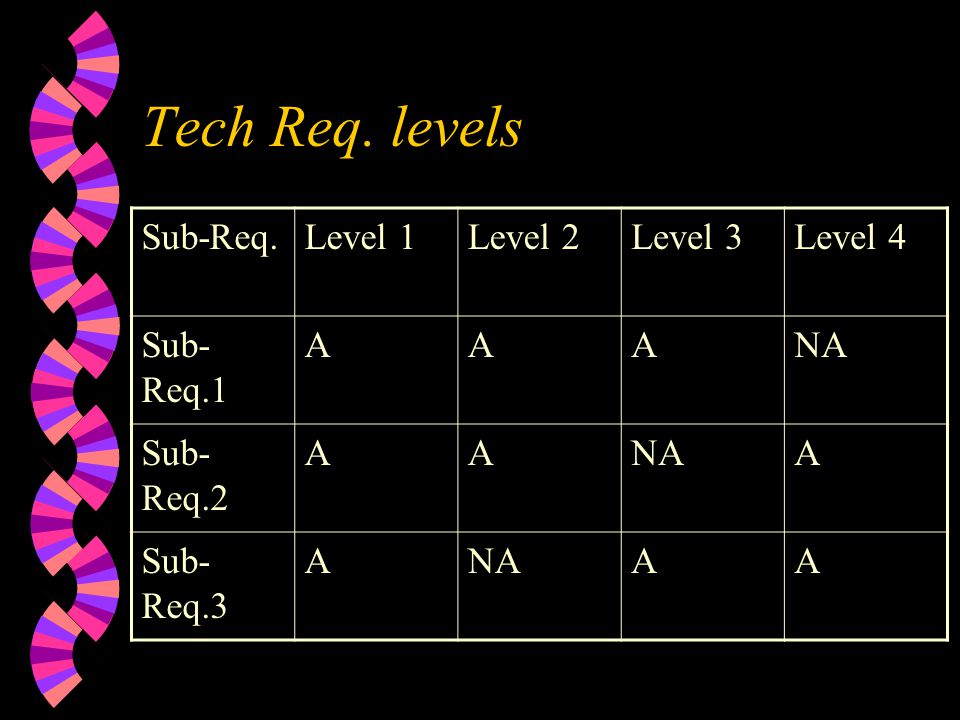

Technical Requirements Level

The Technical Requirements are divided into sub-requirements that have several levels.

21

Tech Req. levels Sub-Req. Level 1 Level 2 Level 3 Level 4 Sub-Req.1 A

NA Sub-Req.2 Sub-Req.3

22

QFD Planning Matrix

23

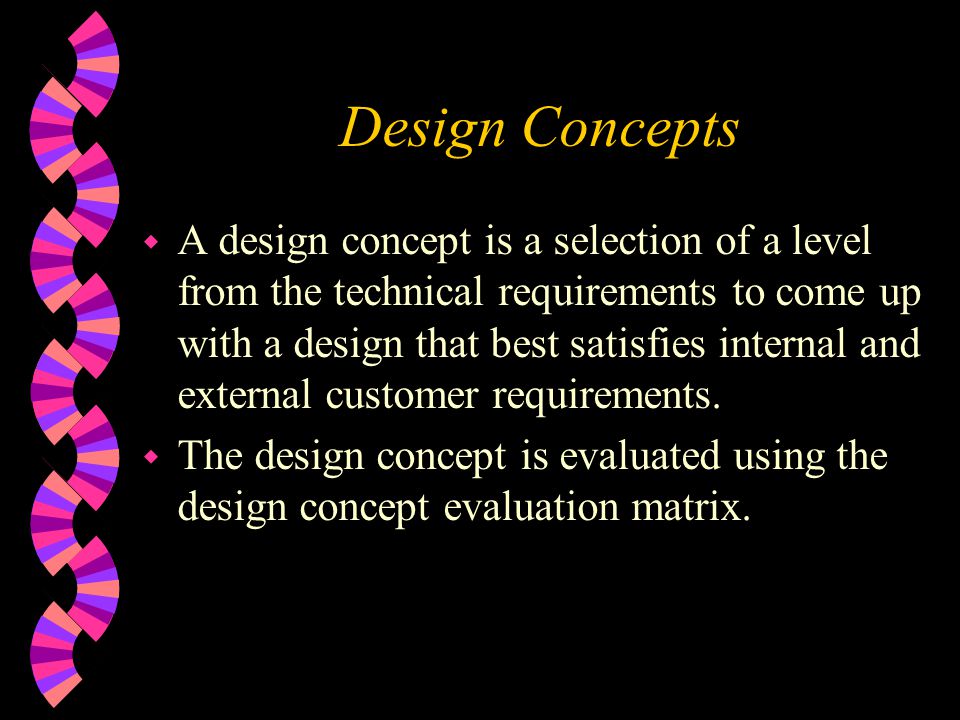

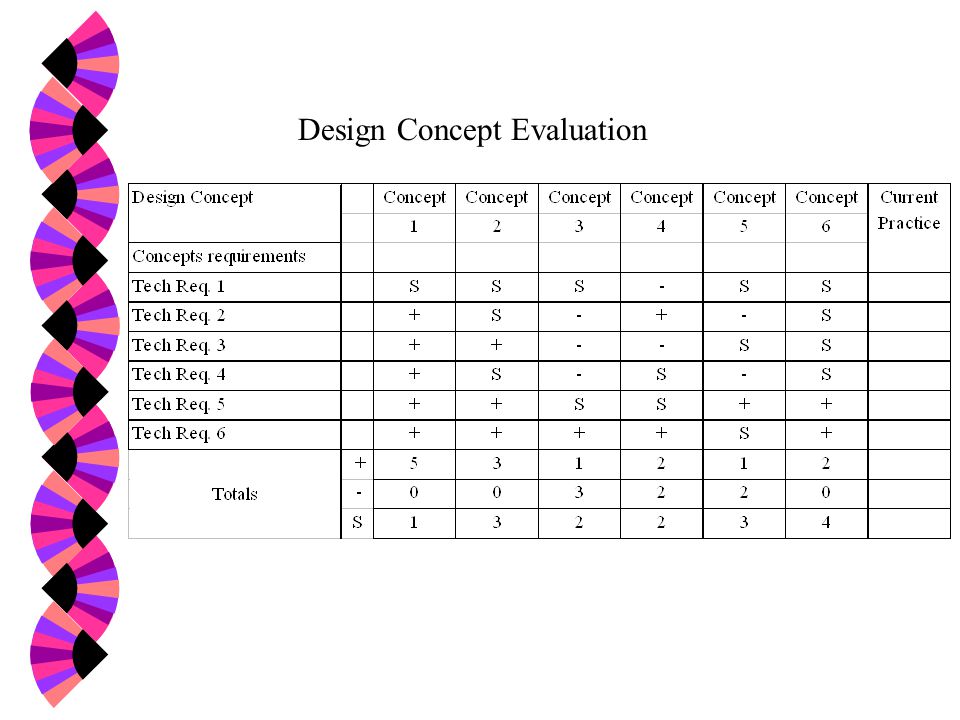

Design Concepts A design concept is a selection of a level from the technical requirements to come up with a design that best satisfies internal and external customer requirements. The design concept is evaluated using the design concept evaluation matrix.

24

Summary of Design Concepts

Numbers in the cells represent the level of each requirement. Numbers in first row are the design concept number. * concept 7 represent current practice.

25

Design Concept Evaluation

26

Conclusion QFD is a method. It is not a panacea. QFD is an effective tool for improving the inventory system. It matches customer requirements with technical requirements. The use of QFD provides a better understanding of the planning process.

27

Conclusion More work could be done to identify more design concepts for evaluation. AHP or a more sophisticated evaluation process can be used to evaluate resulting design concepts. An awareness program must be launched before applying QFD in process, product or service design.

28

Any Questions or Comments?

Thank you. Any Questions or Comments?