Quality Management Techniques | Top Techniques of Quality Management

Mục lục

Overview of Quality Management Techniques

Quality management techniques involve controlling activities and planning to ensure that the service or product is fit for the purpose. The quality of the product makes the reputation of the company and also it fetches the customers for the company. Now if we discuss the quality so it has some parameters which are designed by the respective organization. On these parameters or techniques, the product is created. The parameters may vary from organization to organization.

The quality matters a lot for the customer and company for both because the customer wants quality because he is spending money and he wants good product which is value for money and on the other hand an organization wants to make a good reputation and strong customer base which is only possible if their products are of the utmost quality. Now we will discuss techniques of quality further.

Start Your Free Project Management Course

Project scheduling and management, project management software & others

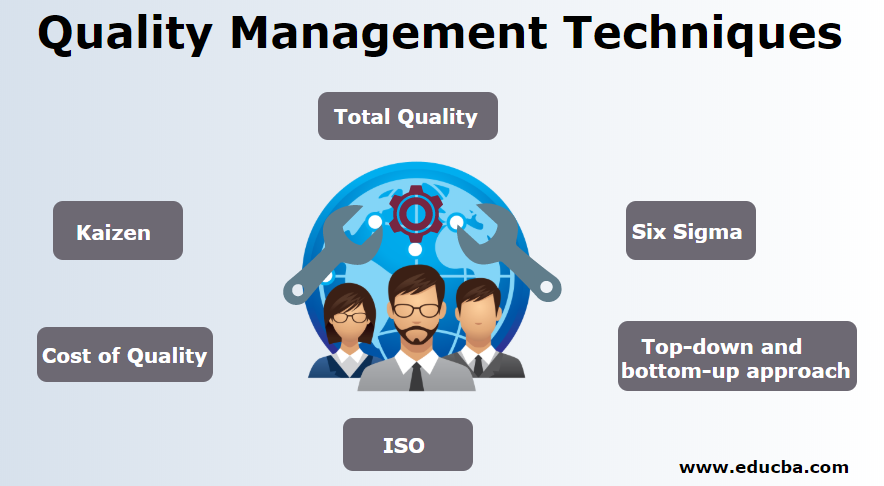

Techniques of Quality Management

There are many techniques for the management of quality in the industries; it may vary according to the requirement in the companies, so we discuss some of the technique which is very much prevailed:

1. Total Quality Management

Total quality management (TQM) is an old technique of quality management, in this very technique focus is given on each and every step of manufacturing to ensure that the quality remained maintained from the inception. This technique is widely used in organizations because it cost-effective and also easy to implement. This technique is also a customer-oriented technique because while implementing this technique customer’s needs are given the most priority. The birth of this technique is traced to Japan. It also saves the resources of the company and also productivity is high. This technique has prevailed basically in the information technology sector etc.

2. Six Sigma

Six Sigma is a very old method of quality management and used widely in industries like mechanical and electrical works. This is a technique in which the focus is one the quality improvement of the product by removing or eliminating the defects which are a hurdle in the quality. The sigma basically is the Greek name of the standard deviation method in mathematics. To understand the six sigma one should understand the value of sigma because its basic concept is based on that, every engineer who works in the industry unit should aware of the six sigma method because whole the work is carried out with that particular technique.

3. Top-down and bottom-up approach

The top-down and bottom-up approaches are very effective types of approaches in this the orders are passed from top officials to lower level and also information is passed from lower level to higher official. If we talk about the top-down approach in this technique the higher officials take a report from the lower officials about the work and quality measures. But on the other hand, the bottom-up approach basically depends upon the information sharing from lower hierarchy to the upper hierarchy about the work done and about the quality parameters which are followed by the workers. The main agenda of this approach is to maintain the quality of the product by co-operating with each level so that a good product is delivered.

4. ISO

It is the “International organization for standardization” a body which gives the certification of quality to the products and also to various type of companies. It is based in Geneva, Switzerland. Every establishment in the world whether it is a company, an industry or other firms should have to take the certification of quality assurance from the ISO. This ISO certification also works as an assurance to the customer that the product is genuine and safe to consume. The ISO tag is there on every product. There are very hard formalities which are to be followed to get the status of ISO approved. So this ISO tag is also the sign of good quality and every industry is running to get this mark to make its product as a genuine product.

5. Cost of Quality

The cost of quality is the difference between the cost of the production including manufacturing, sale and other expenses and cost incurred without any defect during the production. The main idea behind the cost of quality is to make the product cheaper and defect-free. The manager basically focuses on cost reduction and quality improvement so that there is a benefit of the customer and as well of the company. The cost to quality is a new concept and rarely used for quality control because a skillful person is required to make the charts and accounts. But the MNC’s are used this method a large scale.

6. Kaizen

Kaizen is an old Japanese technique to maintain the quality of the product, this particular technique primarily focuses on each and individual level of process and include all types of workers. The agenda is to impact on each level which results in a mass improvement in the whole product. The lower hierarchy of employees is focused because they are the one who works at ground zero and the top management provide every type of facility to them so that they work with full enthusiasm and also the material which is used in the product is wisely selected so that there should not be the quality reduction.

Conclusion

Quality is the utmost important thing, which is handled with care by every company because whole the reputation of the company is based on the quality of the product of that company. The techniques that we discussed above are some of the total techniques and the companies should focus on the adaptation of the right technique, because the quality management techniques may vary from work to work so the holistic and wise approach should be there while selecting the technique for the quality enhancement in the particular industry. Also, the staff should be trained effectively so that they are able to implement it according to the requirements of the production and company and other aspects as well as Perse.

Recommended Articles

This is a guide to Quality Management Techniques. Here we discuss the techniques for the quality management in the industries. You may also have a look at the following articles to learn more –