The Juran Trilogy: Quality Planning | Juran

Mục lục

What is the Juran Trilogy?

The Juran Trilogy, also called Quality Trilogy, was presented by Dr. Joseph M. Juran in 1986 as a means to manage for quality. The traditional approach to quality at that time was based on quality control, but today, the Trilogy has become the basis for most quality management best practices around the world.

In essence, the Juran Trilogy is a universal way of thinking about quality—it fits all functions, all levels, and all product and service lines. The underlying concept is that managing for quality consists of three universal processes:

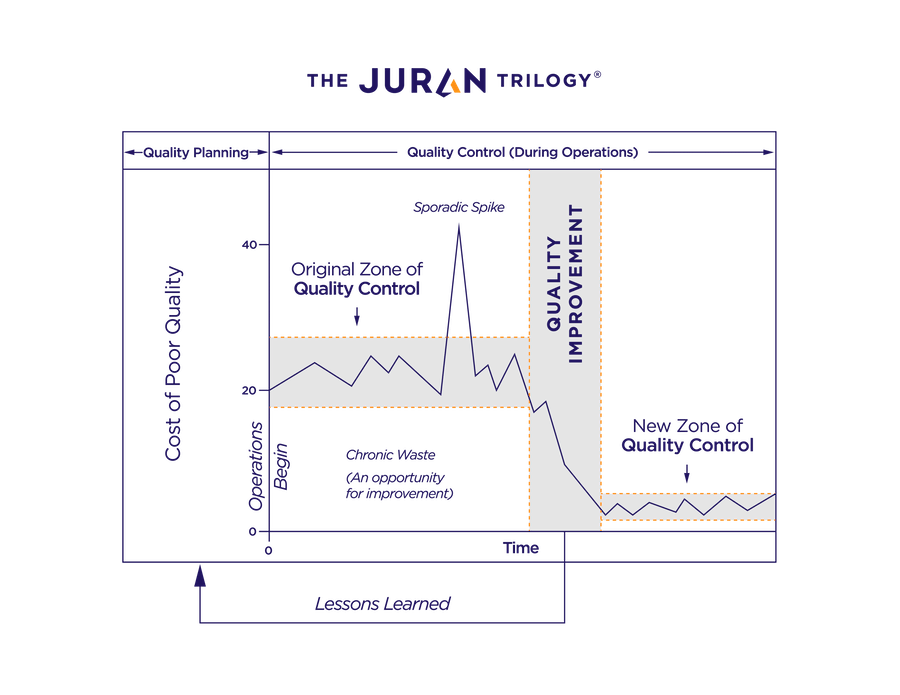

The Juran Trilogy diagram is often presented as a graph, with time on the horizontal axis and cost of poor quality on the vertical axis.

The initial activity is quality planning, or as we refer to it today, ‘quality by design’ – the creation of something new. This could be a new product, service, process, etc. As operations proceed, it soon becomes evident that delivery of our products is not 100 percent defect free. Why? Because there are hidden failures or periodic failures (variation) that require rework and redoing.

In the diagram, more than 20 percent of the work must be redone due to failures. This waste is considered chronic—it goes on and on until the organization decides to find its root causes and remove it. We call it the Cost of Poor Quality. The design and development process could not account for all unforeseen obstacles in the design process.

Under conventional responsibility patterns, the operating forces are unable to get rid of the defects or waste. What they can do is to carry out control—to prevent things from getting worse, as shown. The figure shows a sudden sporadic spike that has raised the failure level to more than 40 percent. This spike resulted from some unplanned event such as a power failure, process breakdown, or human error.

As a part of the control process, the operating forces converge on the scene and take action to restore the status quo. This is often called corrective action, troubleshooting, firefighting, and so on. The end result is to restore the error level back to the planned chronic level of about 20 percent.

The chart also shows that in due course the chronic waste was driven down to a level far below the original level. This gain came from the third process in Juran’s Trilogy—improvement. In effect, it was seen that the chronic waste was an opportunity for improvement, and steps were taken to make that improvement.

Quality Planning (Quality by Design)

The design process enables innovation to happen by designing products (goods, services, or information) together with the processes—including controls—to produce the final outputs. Today many call this Quality By Design or Design for Six Sigma (DFSS)

The Juran Quality by Design model is a structured method used to create innovative design features that respond to customers’ needs and the process features to be used to make those new designs. Quality by Design refers to the product or service development processes in organizations.

Quality Improvement (Lean Six Sigma)

Improvement happens every day, in every organization—even among the poor performers. That is how businesses survive—in the short term. Improvement is an activity in which every organization carries out tasks to make incremental improvements, day after day. Daily improvement is different from breakthrough improvement. Breakthrough requires special methods and leadership support to attain significant changes and results.

It also differs from planning and control as it requires taking a “step back” to discover what may be preventing the current level of performance from meeting the needs of its customers. By focusing on attaining breakthrough improvement, leaders can create a system to increase the rate of improvement. By attaining just a few vital breakthroughs year after year (The Pareto Principle), the organization can outperform its competitors and meet stakeholder needs.

As used here, “breakthrough” means “the organized creation of beneficial change and the attainment of unprecedented levels of performance.” Synonyms are “quality improvement” or “Six Sigma improvement.” Unprecedented change may require attaining a Six Sigma level (3.4 ppm) or 10-fold levels of improvement over current levels of process performance. Breakthrough results in significant cost reduction, customer satisfaction enhancement and superior results that will satisfy stakeholders.

Quality Control (Process Control & Regulatory)

Compliance or quality control is the third universal process in the Juran Trilogy.

The term “control of quality” emerged early in the twentieth century. The concept was to broaden the approach to achieving quality, from the then-prevailing after-the-fact inspection (detection control) to what we now call “prevention (proactive control).” For a few decades, the word “control” had a broad meaning, which included the concept of quality planning. Then came events that narrowed the meaning of “quality control.” The “statistical quality control” movement gave the impression that quality control consisted of using statistical methods. The “reliability” movement claimed that quality control applied only to quality at the time of test but not during service life.

Today, the term “quality control” often means quality control and compliance. The goal is to comply with international standards or regulatory authorities such as ISO 9000.

The Juran Trilogy has evolved over time in some industries. This evolution has not altered the intent of the trilogy. It only changes the names. For instance, traditional goods producers call it QC, QI and QP while another may say QA/QC, CI and DFSS. The Trilogy continues to be the means to present total quality management to all employees looking to find a way to keep it simple.

For more information on Juran’s Trilogy, Quality Planning and how Juran can use it to improve your productivity, please get in touch with the team.