Top 15 5 m in quality in 2023

Below are the best information and knowledge on the subject 5 m in quality compiled and compiled by our own team thoitrangredep:

Mục lục

1. Lean Manufacturing and the 5 M’s | JR Automation

Author: www.jrautomation.com

Date Submitted: 06/23/2019 04:33 AM

Average star voting: 5 ⭐ ( 28219 reviews)

Summary: Lean is an all encompassing philosophy that takes the 5M’s (Man, Material, Machines, Methods and Money), and harmonizes in your manufacturing operations. Learn more here.

Match with the search results: ) and harmonizes or helps orchestrate them together for the best possible outcome in your manufacturing operations….. read more

2. How can Good Hygiene Practices benefit from the 5M method tool?

Author: www.blog-qhse.com

Date Submitted: 11/10/2019 01:52 AM

Average star voting: 4 ⭐ ( 48466 reviews)

Summary: Be on top of good hygiene practices in your business! Methodically identify areas for improvement by following the 5M

Match with the search results: The 5M stands for: Machine (equipment) ; Medium (environment); Method (process) ; Material (raw materials) ; Workforce. With the 5M, you can ……. read more

3. The 5M and Ishikawa method: essential project management tools

Author: managementmania.com

Date Submitted: 07/25/2022 05:11 AM

Average star voting: 5 ⭐ ( 25328 reviews)

Summary: Thanks to the 5M method and its horizontal visualisation tool, faulty phenomena are better identified in project management.

Match with the search results: 5-M Method or 5-Factor Method is a simple method of analyzing the causes and consequences (problems) based on five causes….. read more

![]()

4. The 5 M’s of Kaizen for Managers

Author: zozio.tech

Date Submitted: 11/16/2019 10:10 AM

Average star voting: 5 ⭐ ( 69691 reviews)

Summary: Breaking Kaizen down into the 5 M’s gives managers clear areas of focus for improvement.

Match with the search results: The 5M method is a project management tool for analysing the causes of a problem. It is structured around the 5Ms, which designate the main ……. read more

5. Discover the 5M method

Author: blog.kainexus.com

Date Submitted: 03/27/2022 09:47 PM

Average star voting: 5 ⭐ ( 75256 reviews)

Summary: Identify food safety hazards? Discover the 5Ms

Match with the search results: 1. Manpower. The heart of Kaizen is respect for people. · 2. Machines (Equipment, Technology) · 3. Materials · 4. Methods · 5. Measurements….. read more

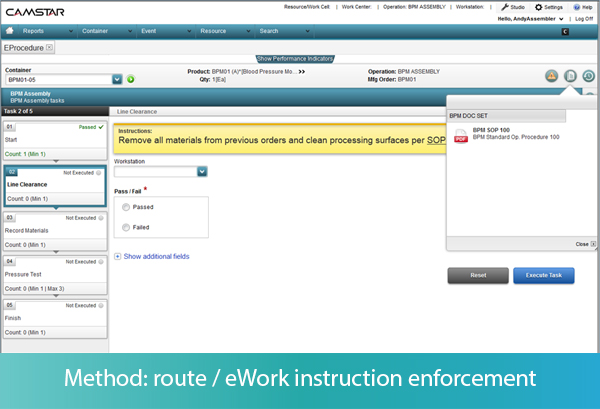

6. Controlling the 5Ms in Pursuit of Product Quality | Part 5 – Method – Opcenter

Author: en.wikipedia.org

Date Submitted: 01/26/2019 04:41 AM

Average star voting: 4 ⭐ ( 56344 reviews)

Summary: There are some basic tenets of manufacturing that we’ve been reviewing in this blog series. Control of the 5Ms of manufacturing – material, man, machine, measure, and method – is critical for creatin…

Match with the search results: The 5M model is a troubleshooting and risk-management model used for aviation safety. … This diagram illustrates the nested/interlocking domains or factors that ……. read more

7. 5M+E

Author: melba.io

Date Submitted: 02/12/2021 09:37 AM

Average star voting: 3 ⭐ ( 10702 reviews)

Summary: The 5M+E model is a management classification system for root causes analysis. It stands for mankind, machine, materials, method, measurement, and environment.

Match with the search results: The 5M method, also called, Ishikawa diagram, is a tool designed by Kaoru Ishikawa, a former Japanese engineer. This diagram takes the form of a ……. read more

8. The 5Ms in Lean Manufacturing – MaintainX

Author: blogs.sw.siemens.com

Date Submitted: 08/15/2020 09:56 PM

Average star voting: 3 ⭐ ( 84739 reviews)

Summary: In manufacturing, problems viewed through a Lean methodology lens fall into five groups: Man, Machine, Materials, Methods, and Measurement.

Match with the search results: Control of the 5Ms of manufacturing – material, man, machine, measure, and method – is critical for creating quality products….. read more

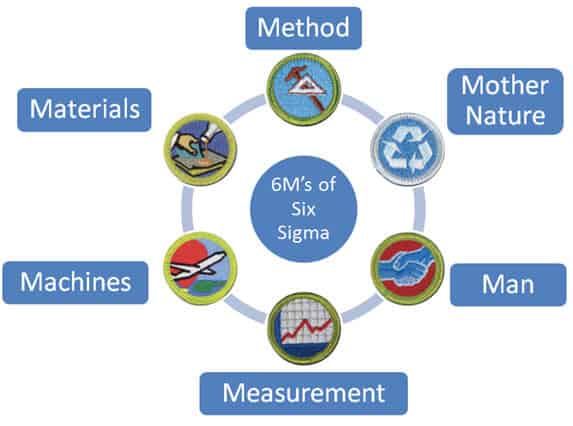

9. 6M’s in Six Sigma (Six Ms or 5Ms and one P or 5M1P)

Author: vksapp.com

Date Submitted: 02/25/2021 02:24 PM

Average star voting: 4 ⭐ ( 79757 reviews)

Summary: In the Analyze phase of DMAIC, we want to use the 6M’s in Six Sigma (Six Ms or 5Ms and one P or 5M1P). This helps root out defects.

Match with the search results: The 5M+E model is a management classification system for root causes analysis. It stands for mankind, machine, materials, method, measurement, ……. read more

10. The 5m model in resource identification – Johnson’s Blog

Author: www.getmaintainx.com

Date Submitted: 02/18/2022 04:27 PM

Average star voting: 5 ⭐ ( 12498 reviews)

Summary: What is the 5m model? 5m model in determining enterprise resources? Let’s find out with Johnson’s Blog through the following article.

Match with the search results: The fishbone diagram and the 5 Whys technique can use the 5Ms detailed above–man, machine, materials, methods, and measurement – to prompt ……. read more

11. What are 5 m in Six Sigma?

Author: www.lean-news.com

Date Submitted: 02/15/2022 05:50 PM

Average star voting: 5 ⭐ ( 72432 reviews)

Summary: Man (in the generic sense), Machine, Material, Method, Measurement, Mother Nature are the categories/the components of variation that contribute to the production

Match with the search results: ) and harmonizes or helps orchestrate them together for the best possible outcome in your manufacturing operations….. read more

12. Using LEAN 5M+E to Discover Probable Causes

Author: sixsigmastudyguide.com

Date Submitted: 03/14/2021 09:15 AM

Average star voting: 4 ⭐ ( 61393 reviews)

Summary:

Match with the search results: The 5M stands for: Machine (equipment) ; Medium (environment); Method (process) ; Material (raw materials) ; Workforce. With the 5M, you can ……. read more

13. The 5 M’s Of Business Management: Organising Them Effectively

Author: leanmanagementireland.com

Date Submitted: 10/06/2021 12:21 AM

Average star voting: 4 ⭐ ( 74123 reviews)

Summary: Managing business organizations has always been a challenge to man since it became scientific. The earliest known accounts of business management in man’s existence tended to be crude, brutish and short.

Match with the search results: 5-M Method or 5-Factor Method is a simple method of analyzing the causes and consequences (problems) based on five causes….. read more

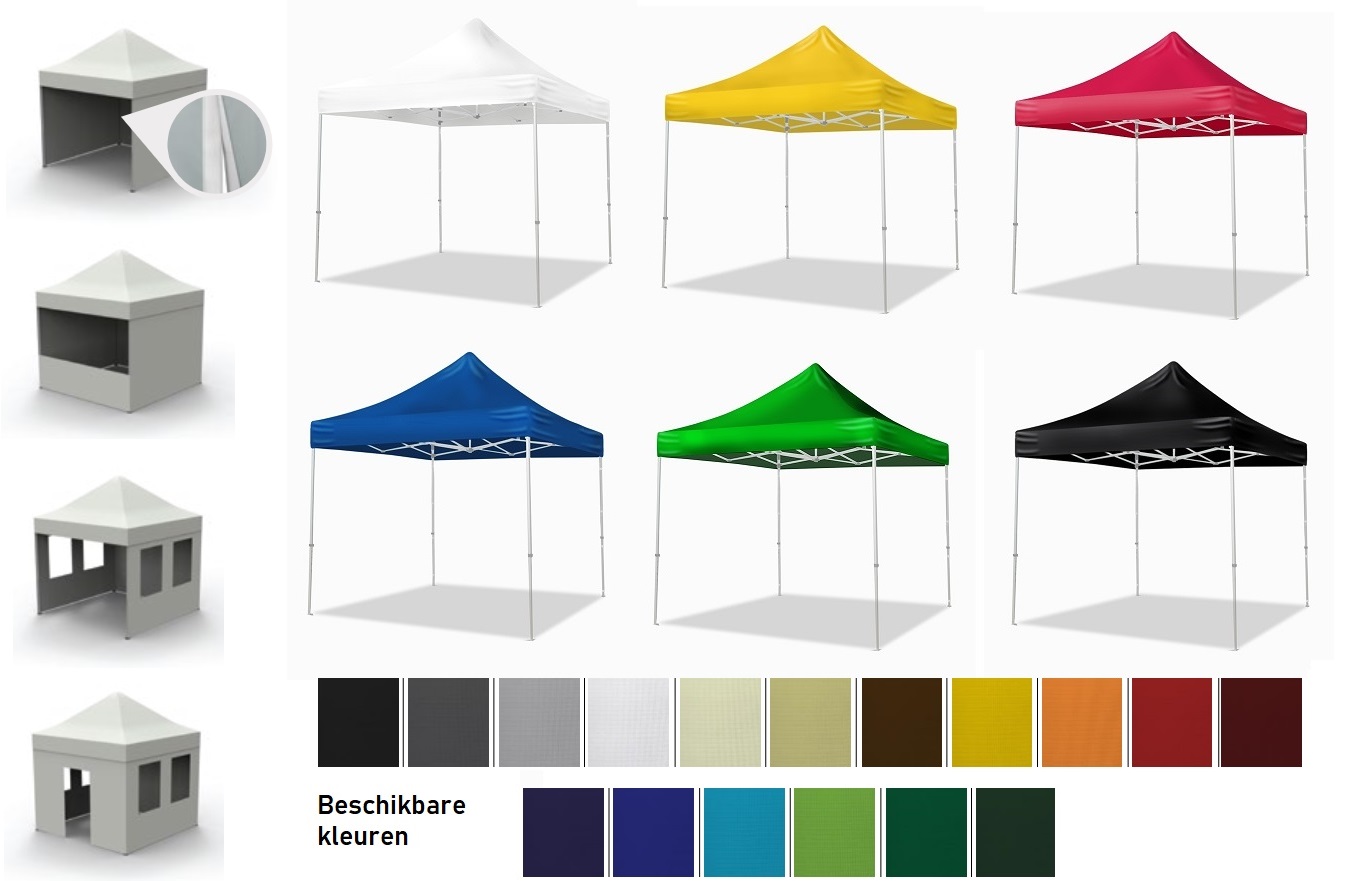

14. Quality wand met ramen – onbedrukt – 4,5 m

Author: theleansuite.com

Date Submitted: 01/22/2019 04:33 PM

Average star voting: 4 ⭐ ( 75406 reviews)

Summary:

Match with the search results: The 5M method is a project management tool for analysing the causes of a problem. It is structured around the 5Ms, which designate the main ……. read more

15. ACT 5 m High Quality stereo audio-aansluitkabel 3,5 mm jack male – male | Viking Direct NL

Author: johnsonvu.com

Date Submitted: 01/02/2022 09:30 PM

Average star voting: 5 ⭐ ( 56363 reviews)

Summary: Heeft u ACT Audiokabel AC3612 Zwart nodig? Die koopt u bij ons voor de beste prijs. Kijk eens op onze website en overtuig uzelf.

Match with the search results: 1. Manpower. The heart of Kaizen is respect for people. · 2. Machines (Equipment, Technology) · 3. Materials · 4. Methods · 5. Measurements….. read more