Total Quality Management and Six Sigma

Mục lục

What is Total Quality Management?

Total Quality Management (TQM) is a management style that involves:

- Commitment from everyone in the organization.

- Dedication to a high level of quality in every process.

- A focus on customer satisfaction.

Breaking down TQM, we see:

- Total (T): Involving the whole organization and every aspect of its business.

- Quality (Q): Fulfilling customer needs and expectations all the time.

- Management (M): Empowering everyone in the organization to achieve high quality results.

Additionally, TQM has a heavy focus on continual improvement. Therefore, we don’t leave a process alone because ‘it’s always worked OK’. Instead, we work to improve and streamline it.

TQM integrates all functions within an organization. Planning, sales, marketing, production, technology, design, and finance are all included under its umbrella. Accordingly, in every department, improvements can be made to meet customer expectations and achieve organizational goals.

Everyone is responsible for quality control; not just the quality assurance team.

The 8 Principles of TQM

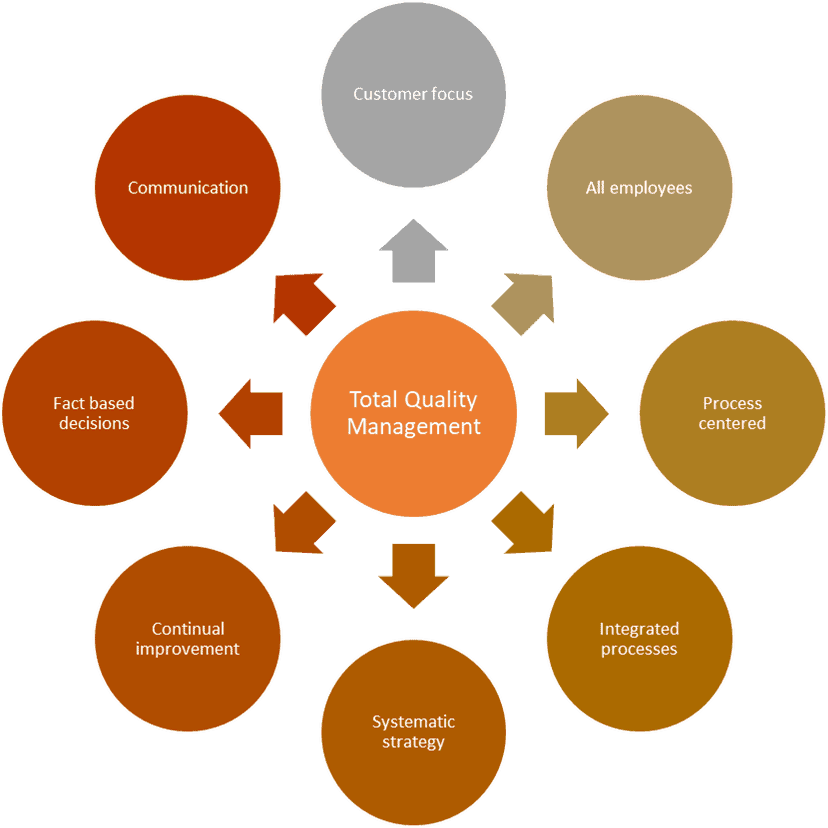

There are eight basic principles in Total Quality Management. These principles, when embraced, work together to improve processes and end results for customer and business alike.

Image: The eight principles of Total Quality Management

1. Customer focus

The success of an organization depends on customer satisfaction. Therefore all improvements must focus on customers and their needs.

2. Total employee involvement

All employees – from CXOs through to the lowest paid worker – need to be involved. Everyone works to increase quality and meet customer expectations.

3. Centered on processes

If you improve your processes, you improve your output. Furthermore, if you improve your output, you improve customer satisfaction. That’s why TQM has such a strong focus on processes. Define, monitor and control your processes to assure quality.

4. Integrated business processes

As different departments evolve in a company, they often develop their own processes. Significantly, it’s very difficult to oversee multiple departments using different processes. TQM requires instead that all key business processes be implemented across the entire company.

5. Systematic, strategic approach

TQM emphasizes implementing strategy in a systematic way. Firstly, you need a strategic plan. This plan needs a strong focus on quality improvements. Then you need a system for implementing the plan. While this might seem simple common sense, many organizations find themselves lacking one of these aspects in their planning.

6. Continual improvement

Look for opportunities to improve. This is a key tenet of TQM. Basically, everyone in a business should be identifying potential improvements. Then, once these have been identified, incorporate them into the strategic plan. Your organisation needs a strong focus on ‘how can we be better?’ rather than ‘this is good enough’.

7. Fact based decisions

Strategic decisions need to be based on facts, not assumptions. You need metrics in place to provide objective, measurable results. That way, you can see exactly what effect various choices have had. Additionally, you can chart progress toward business goals. When progress is not satisfactory, you can change strategy.

8. Communication

Two way communication is essential in TQM. Employees must understand the company’s goals and strategy. For that to happen, Information needs to flow from top to bottom. However, management also must be aware of issues, concerns, and opportunities that staff are aware of. Therefore, information also needs to flow from bottom to top. These don’t just happen by themselves. Set up channels to allow this exchange of information.

History of Total Quality Management

In 1930, Walter Shewhart developed two important management tools:

- Statistical analysis.

- Quality control.

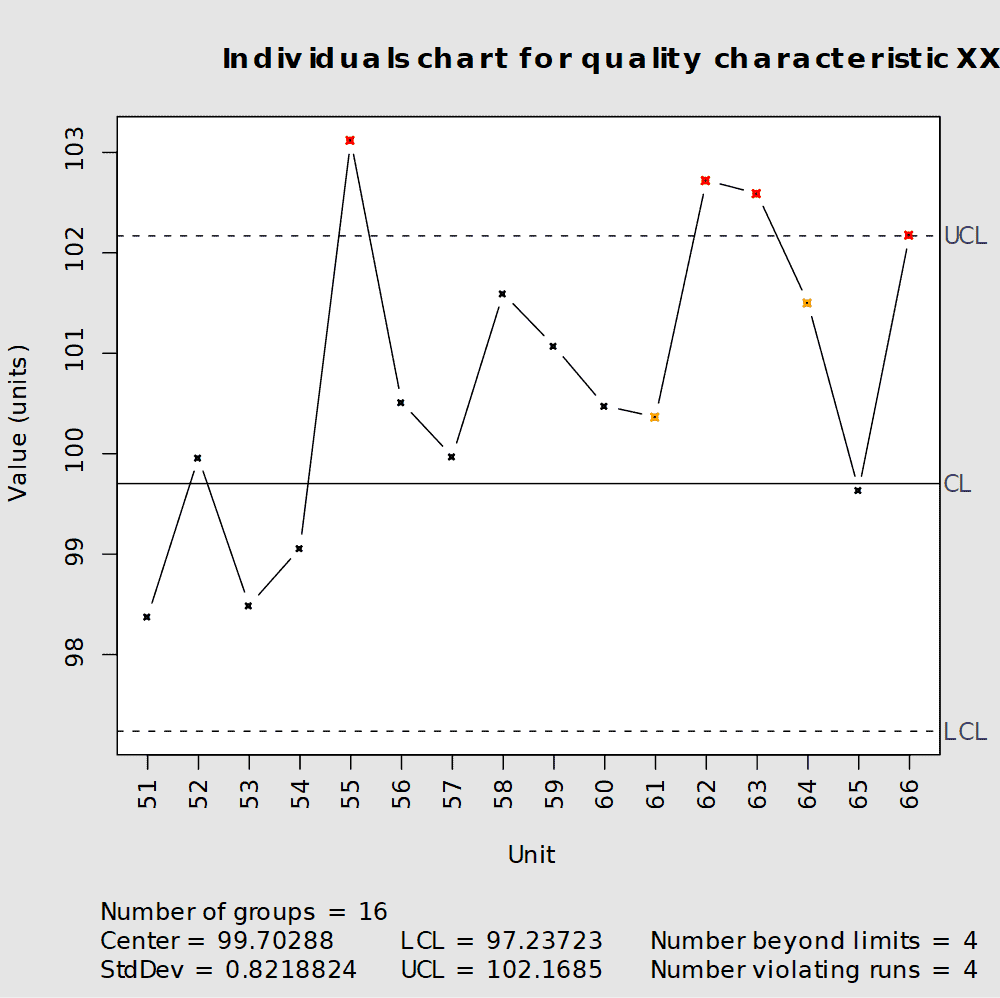

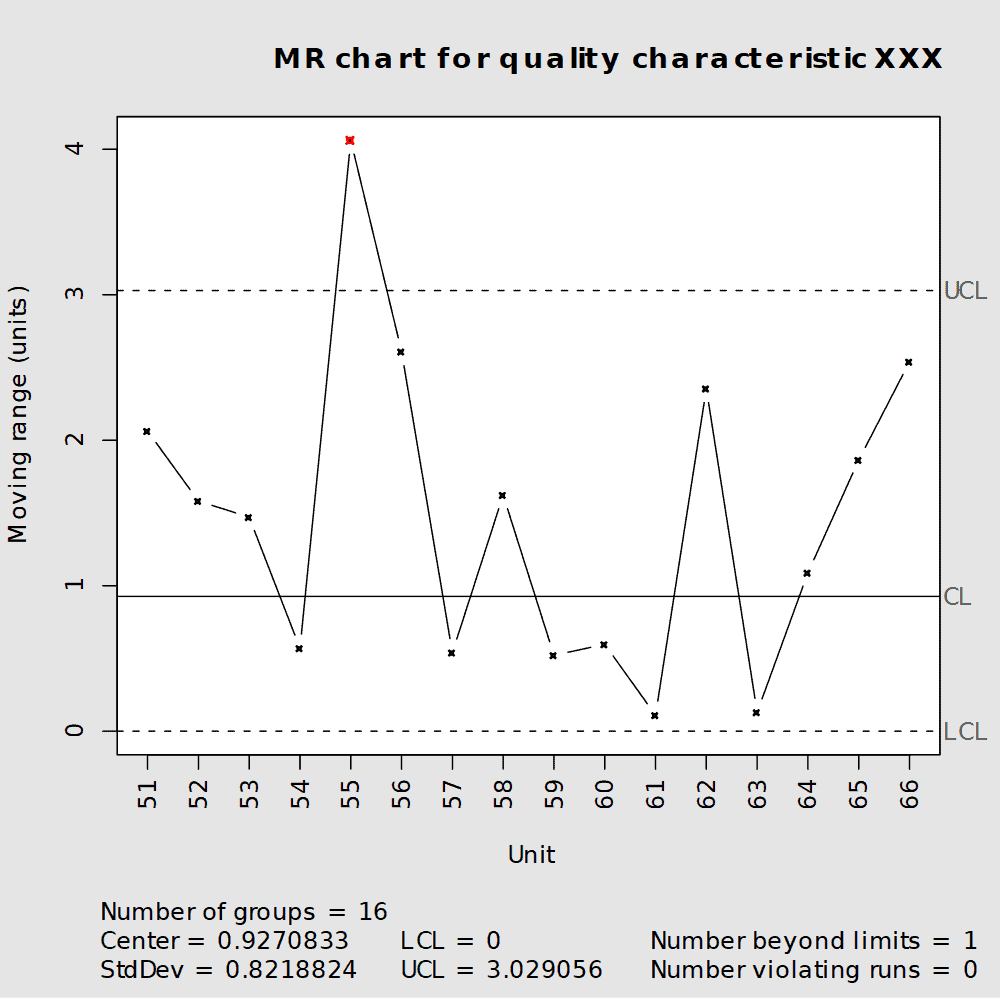

Image: A pair of Shewhart control charts.

By DanielPenfield – Own work, CC BY-SA 3.0

Joseph Juran used these concepts in Western Electric Company. In the 1950s, W. Edwards Deming taught statistical methods and quality control in Japan. Later, he developed these concepts into what would eventually become TQM.

What was the reception?

Japanese companies embraced the new quality control measures. One of the early adopters, Toyota, is now a household name. And the new management methods worked – emphatically so! Japanese production quality soared. By the 1970s and 1980s, manufacturers in Europe and the US were feeling the pinch. They were being outdone. Consumers were losing confidence in them. People were flocking to the better quality products. Companies outside Japan lost customers and income.

In response, US producers reviewed their own processes. In essence, they needed to adopt similar methods. However, they also needed to get everyone on board. Hence the ad campaign on television: If Japan Can… Why Can’t We? Deming’s now-named TQM swept the nation. By the late 1980s, TQM was in popular use in companies across America.

What’s the minimum a company can do to practice TQM?

- Decide that it wants to implement TQM.

- Get support from top managers.

- Convey the decision to all stakeholders.

- Form baselines for customer satisfaction and quality.

- Learn the core principles of TQM.

- Create a TQM implementation plan. Include due dates for every step.

- Identify customer needs and expectations. Then, prioritize them.

- Select processes critical to meeting customer needs.

- Map and analyze those critical processes.

- Plan and implement TQM activities.

- Train staff in the new TQM methods.

- Review progress.

- Revise the plan following the review.

- Seek periodic feedback from all employees.

- Finally, reward and recognize the team for their work.

Benefits of TQM

As Japan discovered in the 1950s, and the rest of the world realized in the decades after, TQM has a lot of benefits. These are the most important ones:

- Improves the quality of products and services offered to customers.

- Boosts employee morale.

- Increases productivity.

- Decreases production costs.

- Raises profits.

- Makes processes more efficient and reliable.

- Engages employees.

- Improves general work environment.

TQM Tools

There are a lot of tools that you can use with TQM. They can help you to:

- Identify problems with quality.

- Analyze issues.

- Evaluate data.

- Identify root causes of problems.

- Measure results.

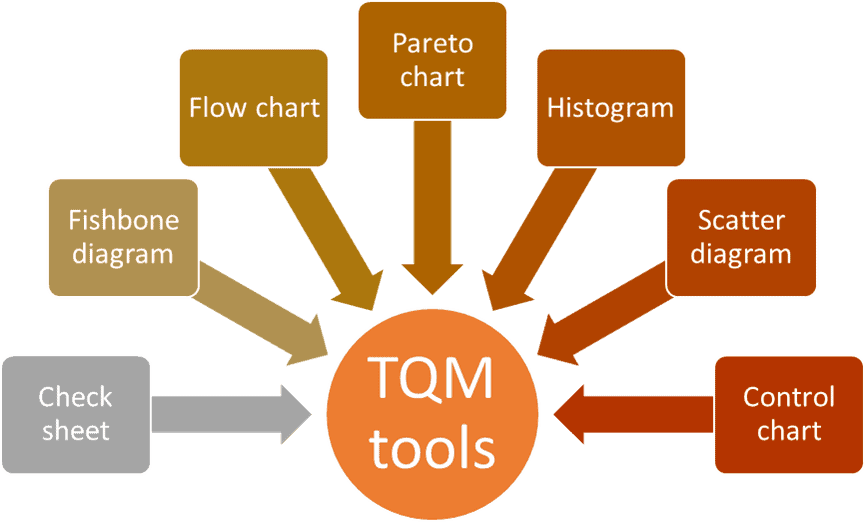

Image: TQM tools

Let’s look at some of the standard TQM tools. You’ll use these to collect data, analyze results, and find problems.

Collect data in real time.

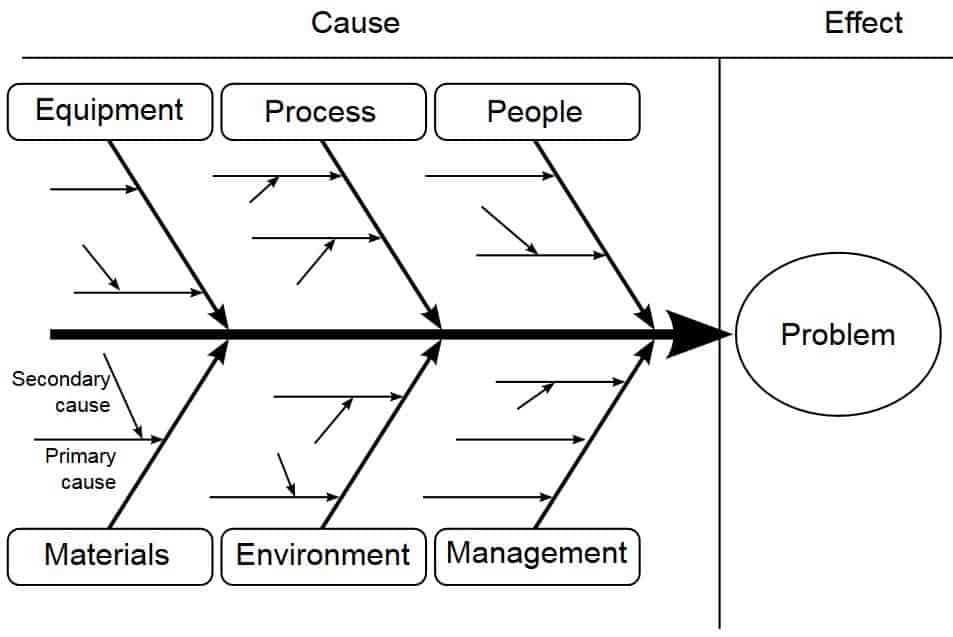

Fishbone diagram in root cause analysis

Also known as an Ishikawa chart. Identify all potential sources of variation. Helps you to find what’s causing variation, and hence defects.

Map processes to better understand their components. You need to understand a process before improving it.

Arrange defects from most to least common. See where your biggest issues lie.

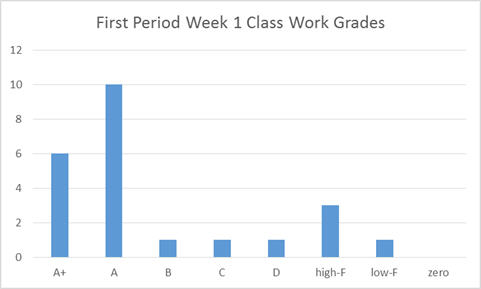

class histogram

Also known as a frequency distribution. That’s because the height of each bar represents the frequency of occurrence.

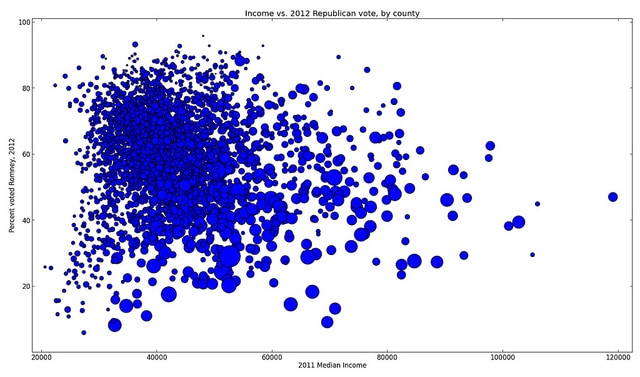

Image: Scatter diagram by Brandon Martin-Anderson

Study the possible relationship between two variables. Chart interactions of the two variables.

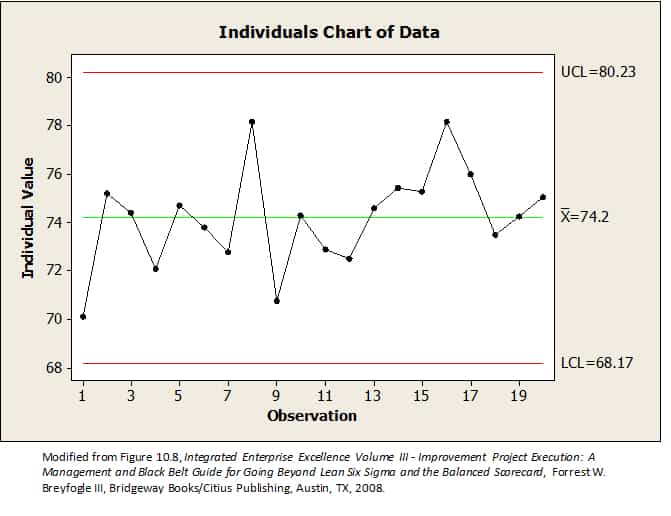

Image: Individuals Control Chart from Smarter Solutions

Study variation over a length of time. Or in other words, look at the changes in a process over a certain period.

Who Uses Total Quality Management?

TQM has been widely used in the manufacturing sector for decades. For instance, Toyota, Motorola, Ford, and Philips were all early adopters. More recently, though, businesses have found applications for it in all sorts of industries. These include but aren’t limited to banking, hospitality, education, tourism, pharmaceuticals, and finance. It’s not limited to manufacture anymore, but it is still used heavily in that industry.

Is Total Quality Management Still Used?

Global competition has only increased the use of TQM. Because it gives businesses a way to manage their quality issues, it stays very relevant. In fact, it’s just as important today as in the 1950s.

Moreover, it’s spawned other concepts. For example:

- International Quality standards such as ISO 9000.

- Business Excellence models.

- Quality awards; for example, the Malcolm Baldrige award and Deming Prize.

All of these are based on the principles of TQM.

Six Sigma and Total Quality Management

Similarities

There are a lot of similarities between Six Sigma and Total Quality Management:

- They’re both methods used to monitor quality of output.

- Both aim to decrease the number of defects and errors.

- Emphasize including every person in the company.

- They’re both process centered.

Differences

Conversely, the two methodologies have some differences:

- TQM focuses on improving the process.

- Six Sigma, on the other hand, focuses on decreasing variation.

Keep in mind, though, that these are both aimed at a similar result: improving output.

Another difference is certification:

- Six Sigma requires rigorous training and testing. There are several levels: green belt, black belt, master black belt, etc.

- TQM doesn’t, for the most part, require any certification. However, it does require training of all staff.

To summarize:

- Six Sigma: Defect focused. Looks for causes of defects and, where appropriate, amends processes. Heavy on certification.

- TQM: Process focused. Looks for improvements that can be made to processes, assuming that better processes will cause fewer errors. Heavy on staff training.

Are TQM and Six Sigma Mutually Exclusive?

TQM was in place long before Six Sigma. So a lot of people think of Six Sigma as a replacement for TQM. Although Six Sigma and TQM can be used independently, they are compatible. In many businesses, the two can be used side by side. Because they each have a different focus, using them together can increase output improvement. At the same time, though, it’s important to delineate how each will be used. And, for that matter, how they will interact.