What Is Quality Assurance?Definition- QA VS Quality Control- Examples

With the industrial revolution and mass production came many new responsibilities. The process of manufacturing became much more complicated The number of products increased insanely compared to older methods.

Changes bring about new concepts. Quality assurance is a concept that is adopted by almost all businesses nowadays.

What is quality assurance? It is a sign of reliability and trust which plays a major role in building strong brand awareness and credibility. This article will explore quality assurance and what difference it makes to a business.

Mục lục

What Is Quality Assurance?

Quality assurance, sometimes referred to as QA, is a system of procedures and policies that aim to guarantee that a specific product meets a set of requirements. Quality assurance is not exclusive to physical products, it can also be applied to businesses which offer services.

Procedures and policies differ according to the nature of the end product or the service offered. However, the system always has the same goal of standardizing the processes and steps that lead to the best final outcome.

The QA methodology follows a corrective and a preventive approach. Corrective means that the system defines a set of actions which must be taken if a mistake or an error occurs during the process of production or delivery.

In other words, what must be done to put the process back on the right track? The preventive approach assigns a set of regulations and policies which eliminate mistakes and minimize the error rate.

What Is Quality Assurance: The Purpose

It’s important to understand the raison d’etre” of quality assurance. Quality “assurance” is there to imply a message of assurance to customers that this business is of high quality.

It is an invitation to them to trust that business, since it has a strict quality assurance policy. As choices grow bigger and bigger, confidence becomes a major factor that controls purchasing decisions.

Customers will choose your business because it has a good reputation and a reliable history of quality services. For these reasons, it is crucial for any business to create a quality assurance policy and to commit itself to a high standard of business.

What Is Quality Assurance: Applications and Examples

If you’re wondering where you can apply quality assurance in your business, here are two common areas where an assurance policy is necessary:

Human Error

In any business, there is a room for human errors. Whether it is a factory, a bank, or a restaurant, employees may make mistakes during making a product or delivering a service. Damages may be financial, or they can directly affect someone’s safety.

Sometimes, a false promise is also a human error. Anyhow, a quality assurance plan must be implemented in order to decrease risk to the minimum. To avoid human errors, sometimes systems are designed to give an alert if a human error is made.

On the other hand, if an employee makes a mistake, there should be a set of well-defined actions to correct the error and compensate for any financial loss or any damage caused by the error. Human error is an area that requires a detailed quality assurance policy.

Design and Manufacture

This point is relevant in case your business sells a product. Design errors can be fatal, especially with products like cars, cell phone gadgets, or equipment.

Quality assurance policies set out a number of tests and evaluations to ensure that the product design is safe and meets the consumer’s needs. In addition, the equipment and the parts used in the manufacture of the products have to match the standard requirements.

Sometimes, when the product is finally out, consumers report a specific fault in its design.

The company should immediately act according to its quality assurance policy and fix the design. Of course, this process should include compensating consumers for any damages caused by the product.

Quality Assurance (QA) VS Quality Control (QC)

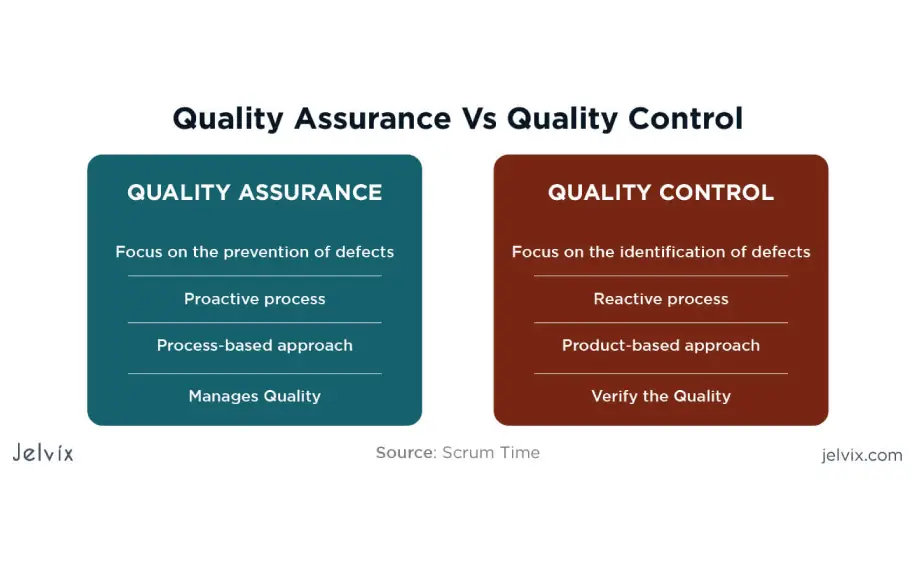

This is usually a point of confusion. The two terms are often used interchangeably. However, they are not the same. Quality assurance is process oriented, while quality control is product oriented.

That means that quality assurance is concerned with the process of fulfilling requirements. It sets the rules which guarantee the best results, in other words, the “prevention” of errors.

On the other hand, quality control is concerned with testing products and detecting their errors, after following the instructions of quality assurance policies. If you have a great assurance policy, but you do not implement quality control, you will never find out if your product actually has defects or not.

There are key differences between the aims of QA and QC. Image credit: Jelvix.com

There are key differences between the aims of QA and QC. Image credit: Jelvix.com

Quality assurance is a strategy of prevention, while quality control is a strategy of detection.

This does not contradict with what is mentioned earlier about the fact that quality assurance employs a preventive approach and a corrective one. In brief, although the two terms have the same target and are closely related, they are not the same thing.

What Is Quality Assurance: Implementation to Your Business

It may be obvious why a global brand or a car manufacturing company will need to implement quality assurance. To a huge company, quality is the core factor controlling its number of sales.

Moreover, brand products are well-known to everyone around the world and a reported defect will harm its reputation worldwide causing massive financial damage.

In the meantime, if you own a start-up business or a hairdressing salon, do you need quality assurance?

The answer is yes, let us explain why.

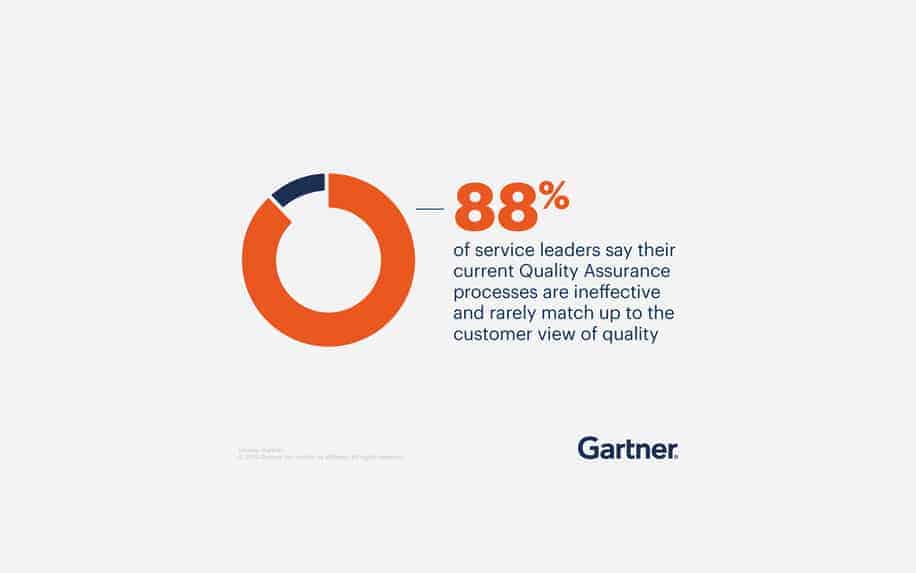

It has been mentioned earlier that the purpose of quality assurance is showing to your customers that your business is trustworthy. This implies that “customer satisfaction” is the ultimate goal of the whole process.

In order to satisfy your customers, you need to define exactly what their needs are. This brings us to the main point. Managers build quality assurance policies based on customer feedback.

The quality “standards” are nothing but the combination of customers’ preferences, requests, and complaints.

If you do not have a system that keeps track of your clients’ needs, or if you deliver your products or services randomly without a specific formula, then you are not in control of the quality of your business.

Having a quality assurance system, even a simple and basic one, organizes the process and makes your business look better.

Quality Assurance: Certification

Organizations exist to certify businesses for their quality assurance policies. Some of these entities are local and certify your company within the country your business operates in.

Other organizations, such as the ISO, are international and they give your business a worldwide certification.

These organizations examine each company that applies for a certificate. Your business goes through a number of tests and evaluations before it gets certified.

Moreover, a committee re-evaluates the business every once in a while to ensure that it still follows the standards. This gives the certified company prestige and trust which is of course highly important to their business.

Quality Assurance in a Nutshell

The answer to the question of “what is quality assurance?” includes several aspects. In brief, quality assurance is a system of rules and regulations to organize how a company should function in order to meet the standard requirements.

Under this umbrella-term, there are many processes and observations that must be executed in order to perfect the final outcome. This thrive for perfection benefits the market and, ultimately, consumers.