Top 22 5s quality in 2023

Below are the best information and knowledge on the subject 5s quality compiled and compiled by our own team thoitrangredep:

Mục lục

1. Lean Thinking and Methods – 5S | US EPA

Author: www.epa.gov

Date Submitted: 04/05/2020 06:06 AM

Average star voting: 4 ⭐ ( 19426 reviews)

Summary: introduction to 5S

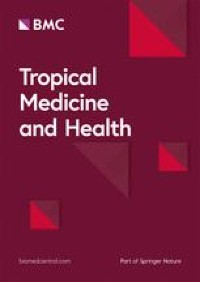

Match with the search results: The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), …. read more

2. 5S – What are The Five S’s of Lean? | ASQ

Author: asq.org

Date Submitted: 02/23/2019 08:08 PM

Average star voting: 4 ⭐ ( 16013 reviews)

Summary: To avoid waste, enterprise organizations should pass through lean before agile. Learn the difference between agile and lean with this tutorial from ASQ.org.

Match with the search results: 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity….. read more

3. 5S | 5S Methodology | What is 5S | Quality-One

Author: quality-one.com

Date Submitted: 04/04/2020 11:59 PM

Average star voting: 3 ⭐ ( 15692 reviews)

Summary: The 5S Method is a standardized process that when properly implemented creates and maintains an organized, safe and efficient workplace. Learn more about 5S.

Match with the search results: The 5S Method is a standardized process that when properly implemented creates and maintains an organized, safe, clean and efficient workplace. Improved visual ……. read more

4. 5S for Workplace Improvement | Quality Gurus

Author: www.qualitygurus.com

Date Submitted: 11/19/2022 08:54 PM

Average star voting: 3 ⭐ ( 53022 reviews)

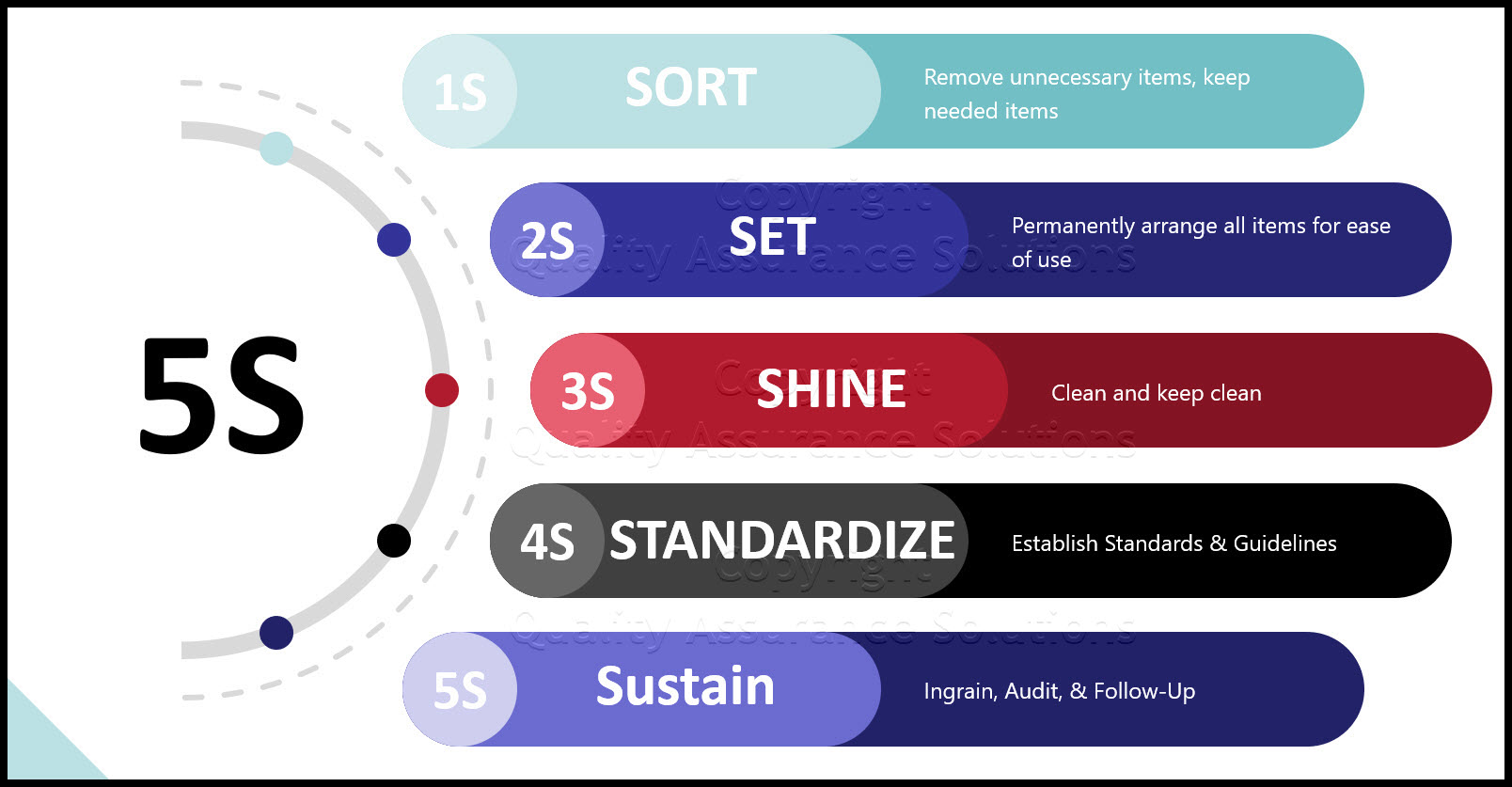

Summary: 5S is a method for workplace organization and improvement that originated in Japan. It stands for five (5) Japanese words that start with the letter ‘S’: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. The English translation of these terms is sort, set in order, shine, standardize, and sustain. By implementing

Match with the search results: …. read more

5. What is 5S? 5S System is explained including tips on getting a 5S program started.

Author: www.5stoday.com

Date Submitted: 12/25/2019 09:55 AM

Average star voting: 3 ⭐ ( 54559 reviews)

Summary:

Match with the search results: 5S is a method for workplace organization and improvement that originated in Japan. It stands for five (5) Japanese words that start with the letter ‘S’: ……. read more

6. Applying 5S in the Manufacturing Industry | Lean Production

Author: www.leanproduction.com

Date Submitted: 12/02/2019 04:33 AM

Average star voting: 3 ⭐ ( 52128 reviews)

Summary: What is the 5S production system? Learn how to implement 5S activities as the foundation of TPM

Match with the search results: 5S is a system for organizing spaces so work can be performed efficiently, effectively, and safely. This system focuses on putting everything where it ……. read more

7. What is the 5s System? | Definitions, Core Concepts & Principles | Graphic Products

Author: www.graphicproducts.com

Date Submitted: 01/26/2021 09:09 AM

Average star voting: 5 ⭐ ( 22296 reviews)

Summary: The 5S system is a lean methodology that improves workplace efficiency and eliminates waste. This article reviews the five steps, common uses, and more.

Match with the search results: Learn how to implement 5S activities as the foundation of TPM. … their workspace and helps to instill a culture of quality, productivity, and improvement….. read more

8. Applicability of the 5S management method for quality improvement in health-care facilities: a review – Tropical Medicine and Health

Author: tropmedhealth.biomedcentral.com

Date Submitted: 09/21/2021 06:08 PM

Average star voting: 3 ⭐ ( 25518 reviews)

Summary: The 5S management method (where 5S stands for sort, set in order, shine, standardize, and sustain) was originally implemented by manufacturing enterprises in Japan. It was then introduced to the manufacturing sector in the West and eventually applied to the health sector for organizing and standardizing the workplace. 5S has recently received attention as a potential solution for improving government health-care services in low- and middle-income countries. We conducted a narrative literature review to explore its applicability to health-care facilities globally, with a focus on three aspects: (a) the context of its application, (b) its impacts, and (c) its adoption as part of government initiatives. To identify relevant research articles, we researched public health databases in English, including CINAHL, PubMed, ScienceDirect, and Web of Science. We found 15 of the 114 articles obtained from the search results to be relevant for full-text analysis of the context and impacts of the 5S application. To identify additional information particularly on its adoption as part of government initiatives, we also examined other types of resources including reference books, reports, didactic materials, government documents, and websites. The 15 empirical studies highlighted its application in primary health-care facilities and a wide range of hospital areas in Brazil, India, Jordan, Senegal, Sri Lanka, Tanzania, the UK, and the USA. The review also found that 5S was considered to be the starting point for health-care quality improvement. Ten studies presented its impacts on quality improvements; the changes resulting from the 5S application were classified into the three dimensions of safety, efficiency, and patient-centeredness. Furthermore, 5S was adopted as part of government quality improvement strategies in India, Senegal, Sri Lanka, and Tanzania. 5S could be applied to health-care facilities regardless of locations. It could be not only a tool for health workers and facility managers but also a strategic option for policymakers. They could consider 5S as the starting point of a government-led quality improvement initiative for improving safety, efficiency, or patient-centeredness aspects particularly in low- and middle-income countries. However, the evidence base, particularly in resource-poor settings, must be expanded.

Match with the search results: What Is the 5S System? · 1. Sort · 2. Set In Order · 3. Shine · 4. Standardize · 5. Sustain….. read more

9. 5S System

Author: safetyculture.com

Date Submitted: 11/23/2022 10:17 PM

Average star voting: 3 ⭐ ( 27741 reviews)

Summary: Learn more about the 5S System meaning and how you can apply this to practically improve processes that lead to better production results. Read more.

Match with the search results: The 5S management method (where 5S stands for sort, set in order, shine, standardize, and sustain) was originally implemented by manufacturing ……. read more

10. 5S Lean Methodology, Systems & Principles – Training & Research Page

Author: www.toolshero.com

Date Submitted: 05/05/2019 12:35 PM

Average star voting: 4 ⭐ ( 29114 reviews)

Summary: Learn about 5S principles, systems, methodology, applications & research from the experts. Read to learn more about 5S.

Match with the search results: It applies the five principles: Sort (seiri), Set in order (seiton), Shine (seiso), Standardize (seiketsu), and Sustain (shitsuke). These principles were ……. read more

11. Learn lean 5S best practices.

Author: www.creativesafetysupply.com

Date Submitted: 10/18/2022 11:48 AM

Average star voting: 3 ⭐ ( 44343 reviews)

Summary: This page describes lean 5S best practices which includes 5S housekeeping, 5S checklists and 5S audits. Improve your business with these 5S principles.

Match with the search results: The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), …. read more

12. 5S – Continuous Improvement Toolkit

Author: en.wikipedia.org

Date Submitted: 08/30/2019 11:16 AM

Average star voting: 4 ⭐ ( 45596 reviews)

Summary:

Match with the search results: 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity….. read more

13. What is 5S Methodology: 5s Implementation Plan

Author: www.youtube.com

Date Submitted: 05/15/2021 01:11 AM

Average star voting: 4 ⭐ ( 75369 reviews)

Summary: This article talks about the 5s methodology, why should you use, and learn how to implement the 5s Methodology to achieve workplace efficiency. Read to know more.

Match with the search results: The 5S Method is a standardized process that when properly implemented creates and maintains an organized, safe, clean and efficient workplace. Improved visual ……. read more

14. 5S BASIC – Quality Engineer Stuff

Author: www.quality-assurance-solutions.com

Date Submitted: 04/21/2022 01:28 AM

Average star voting: 3 ⭐ ( 31210 reviews)

Summary: Learn about the 5s basics? 5S methodology, which is used in Japanese era. 5S is important methodology to reduce waste and improvement activity. 5S basics…

Match with the search results: …. read more

15. 5S vs. Six Sigma: Which One is Right For Your Organization?

Author: citoolkit.com

Date Submitted: 05/25/2021 01:05 PM

Average star voting: 5 ⭐ ( 46846 reviews)

Summary: 5S and Six Sigma are great methods for improving efficiency. Learn what both entail, how they differ, and which one might better suit your goals.

Match with the search results: 5S is a method for workplace organization and improvement that originated in Japan. It stands for five (5) Japanese words that start with the letter ‘S’: ……. read more

16. 5S Quality system [ 5S METHODOLOGY ] What is ‘5S’ Methodology? | 5S Workplace Methodology

Author: www.simplilearn.com

Date Submitted: 11/05/2021 11:08 PM

Average star voting: 5 ⭐ ( 73198 reviews)

Summary: 5S is a workplace organization method that uses a list of five Japanese words: seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). These have been translated as “Sort”, “Set In order”, “Shine”, “Standardize” and “Sustain”.

Match with the search results: 5S is a system for organizing spaces so work can be performed efficiently, effectively, and safely. This system focuses on putting everything where it ……. read more

17. 5s Methodology & Principles in Project Management

Author: www.emerald.com

Date Submitted: 12/05/2019 10:37 AM

Average star voting: 5 ⭐ ( 82126 reviews)

Summary: What is 5s Methodology and What does 5s Stands For? 5s is a lean methodology which employs Seiri, Seiton, Seiso, Seiketsu, and Shitsuke principles.

Match with the search results: Learn how to implement 5S activities as the foundation of TPM. … their workspace and helps to instill a culture of quality, productivity, and improvement….. read more

18. Reliabilityweb The 5S Method of Improvement – Enhancing Safety, Productivity and Culture

Author: qualityengineerstuff.com

Date Submitted: 06/18/2021 07:55 PM

Average star voting: 4 ⭐ ( 59543 reviews)

Summary: Reliability Web

Match with the search results: What Is the 5S System? · 1. Sort · 2. Set In Order · 3. Shine · 4. Standardize · 5. Sustain….. read more

19. 5s Principles, Processes and Tools for Quality Improvement

Author: digital.ahrq.gov

Date Submitted: 03/16/2022 03:50 PM

Average star voting: 4 ⭐ ( 65240 reviews)

Summary: The 5S principle is a quality improvement tool used for organising the workspace. This article covers the 5S principles, processes and tools.

Match with the search results: The 5S management method (where 5S stands for sort, set in order, shine, standardize, and sustain) was originally implemented by manufacturing ……. read more

20. 5S for Small Businesses: The Benefits and Principles | TQMI

Author: www.heattreat.net

Date Submitted: 10/07/2019 07:09 PM

Average star voting: 5 ⭐ ( 28070 reviews)

Summary: The goal of 5S is to improve work efficiency, safety, and quality. It’s a systematic way to keep everything in its place. Learn about the principles and benefits of 5S.

Match with the search results: It applies the five principles: Sort (seiri), Set in order (seiton), Shine (seiso), Standardize (seiketsu), and Sustain (shitsuke). These principles were ……. read more

21. 5s Quality Systems Training | Online Course | Train4Academy

Author: www.ccoconsulting.com

Date Submitted: 05/26/2022 06:42 PM

Average star voting: 3 ⭐ ( 99075 reviews)

Summary: An online 5s Quality Systems Training course to make 5s techniques

understandable & allow staff to digest the principles step by step. CPD Accredited. 60 Minute Course.

Match with the search results: The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), …. read more

![]()

22. What is 5S? Understand how 5S helps productivity

Author: www.linkedin.com

Date Submitted: 11/05/2019 11:12 PM

Average star voting: 4 ⭐ ( 85981 reviews)

Summary: Curious about 5S and what it can do for your facility? Answer the question: What is 5S? With our bookmark-able infographic.

Match with the search results: 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity….. read more

![]()

![5S Quality system [ 5S METHODOLOGY ] What is '5S' Methodology? | 5S Workplace Methodology](https://media.licdn.com/dms/image/C4E12AQEJTi5Ez6E_cA/article-cover_image-shrink_720_1280/0/1600757116960?e=2147483647&v=beta&t=soQbjSYdjs0QO9FCnmGMFaIq3VSfAoK6m30FfGF1ylE)